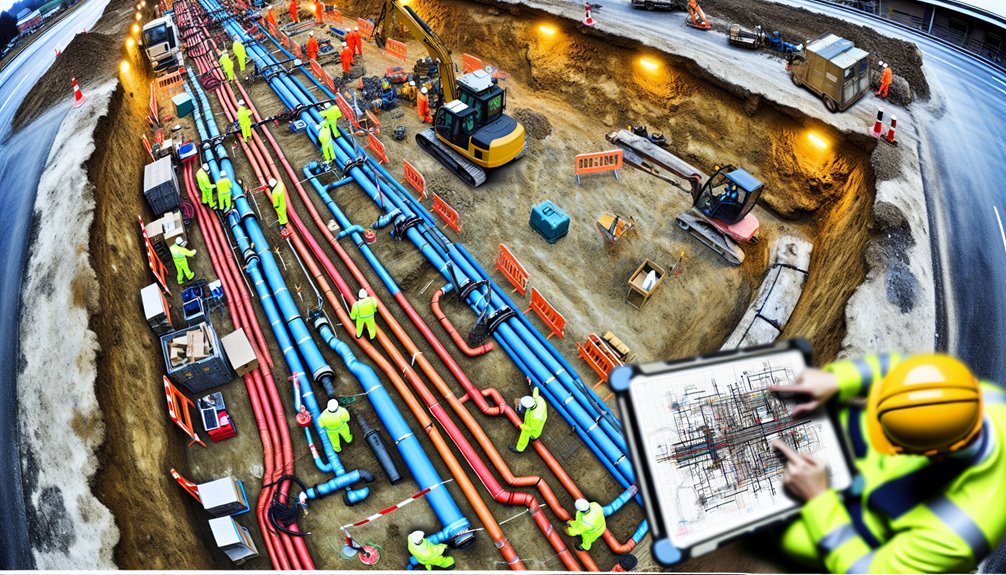

When you're tackling underground utility construction, starting with a thorough pre-construction site assessment is essential. You'll want to leverage cutting-edge technologies like Ground-penetrating radar (GPR) and GIS mapping to identify exactly where existing utilities are located. This step not only keeps your team safe but also protects infrastructure and avoids costly repairs. It's important to grasp the depth of planning and precision required in these operations. Let's explore how adopting stringent safety protocols and enhancing communication can markedly lower the risks involved.

Comprehensive Pre-Construction Site Assessments

Before commencing any underground utility construction, it's important to conduct a thorough pre-construction site assessment to mitigate risks and guarantee safety.

You'll start with a desk study, gathering existing utility maps, as-builts, and other relevant documents. Employing AI-powered solutions during this phase enhances data accuracy, essential for identifying potential underground hazards early.

Your site evaluation isn't just about collecting data; it's about integrating historical data to create a preliminary view of the utilities in your project area.

This step is significant for planning and avoiding costly mistakes. By ensuring that the gathered data is precise and comprehensive, you're setting the groundwork for a successful and innovative construction project that not only meets but exceeds safety standards. To further enhance safety, using Ground-penetrating radar (GPR) technology can effectively identify non-metallic utilities such as plastic pipes or fiber optics that traditional methods might miss.

Utilization of Advanced Mapping Technologies

As you shift into implementing GIS mapping in your projects, you'll harness the power of overlaying essential utility data onto geographical maps to enhance safety and decision-making. The benefits of 3D imaging are also considerable; by creating accurate, detailed visual representations of subterranean environments, you greatly reduce the risk of accidental utility strikes. These technologies not only guarantee compliance with safety standards but also streamline the entire construction process. Furthermore, the integration of multisource data mapping solutions combines satellite data, topographical maps, and AI for improved accuracy, significantly mitigating risks associated with underground utility construction.

Implementing GIS Mapping

Implementing GIS mapping in underground utility construction leverages advanced technologies to secure the accuracy and safety of your projects.

By utilizing GIS, GPS, and other precise data-gathering tools like GPR and electromagnetic locators, you're equipped to pinpoint the exact location, depth, and type of subterranean utilities.

This GIS integration not only enhances mapping accuracy but also facilitates the creation of thorough, multi-layered maps. These detailed maps help in detecting unrecorded "phantom lines" which could pose significant risks.

Additionally, real-time data sharing enabled by GIS technologies guarantees that all stakeholders—from field workers to project managers—have immediate access to critical information, thereby improving decision-making and reducing the likelihood of excavation mishaps.

Benefits of 3D Imaging

Utilizing advanced mapping technologies, 3D imaging greatly enhances the accuracy and detail of underground utility maps. By incorporating laser scans, ground-penetrating radar, and other sensors, this method captures highly detailed data, crafting maps with up to 99.8% precision.

You'll see benefits in safety, as these detailed maps considerably reduce the risk of damaging underground utilities during construction. Enhanced project collaboration emerges, as teams can access and share 3D visualizations, improving communication and coordination.

Additionally, the integration of 3D data with CAD applications supports meticulous planning and execution, streamlining your construction projects and ensuring you're compliant with regulatory standards.

Embrace these 3D visualization techniques to maintain safety, boost efficiency, and cut costs on your site.

Implementation of Effective Communication Protocols

To mitigate risks in underground utility construction, it's crucial to implement effective communication protocols that establish clear and efficient channels among all stakeholders.

Here's how you can guarantee robust communication strategies:

- Define Clear Communication Channels:

- Establish a transparent chain of command and use a centralized communication hub to streamline information exchange.

- Select Appropriate Communication Methods:

- Adapt communication methods based on the urgency and complexity of information, ranging from emails for updates to real-time tools for immediate discussions.

- Guarantee Accurate and Timely Information Exchange:

- Conduct thorough utility data collection and maintain consistent data management practices to keep all stakeholders well-informed and aligned with the project's progress.

Adoption of Rigorous Safety Training Programs

You must implement mandatory safety courses tailored to the specific needs of underground utility construction, ensuring all team members are well-versed in critical safety protocols and compliance standards.

Continuous updates to these training programs are essential, as they keep your team current with the latest safety practices and technological advancements.

This proactive approach not only enhances worker safety but also aligns with regulatory requirements, protecting your project from costly penalties and delays.

Mandatory Safety Course Implementation

In addressing the critical need for enhanced safety in underground utility construction, adopting mandatory safety courses is imperative.

You'll guarantee adherence to mandatory training protocols and enhance safety compliance measures. Here's what to focus on:

- In-depth Regulatory Understanding: Grasp every detail from OSHA Underground Construction Standards to state regulations, guaranteeing every team member isn't just aware but proficient.

- Proactive Hazard Management: Equip your team to recognize and respond to site-specific hazards, including atmospheric conditions and ground stability, reducing risk proactively.

- Comprehensive Site and Equipment Handling: From controlling site access to mastering the use of PPE, guarantee your procedures promote a culture of safety that pervades every aspect of the operation.

Continuous Training Updates

Adopting rigorous safety training programs, such as continuous training updates, guarantees that your team remains at the forefront of industry standards and safety protocols.

Utilizing advanced technologies like VR and simulation-based training enhances training effectiveness. These tools simulate real-world scenarios, from handling HDD equipment to maneuvering complex underground utilities, preparing your team for any challenge.

Ascertain your training includes the latest regulatory updates and compliance standards, integrating continuous learning on environmental and safety protocols. This proactive approach not only reduces the risk of accidents and equipment damage but also guarantees adherence to evolving regulations.

Regularly update your training modules to keep pace with technological advancements and regulatory changes, securing a culture of safety and innovation within your workforce.

Regular Maintenance and Inspection of Equipment

Guarantee all necessary notifications are made before beginning equipment inspections or operations to prevent unintended damage to underground utilities.

In the domain of underground utility construction, regular maintenance and inspection of equipment are pivotal.

Here's a concise guide to guarantee you're on top of it:

- Preventive Maintenance: Commit to routine checks and updates of your equipment. This not only prolongs its life but also guarantees operational safety and efficiency.

- Equipment Inspections: Before any operation, thoroughly inspect tools and PPE for defects. Replace any faulty items immediately to safeguard against potential hazards.

- Innovative Monitoring: Utilize IoT devices to monitor and predict equipment failures before they occur, markedly reducing downtime and repair costs.

Adhering to these steps will notably enhance safety and efficiency in your projects.

Strategic Planning for Emergency Response

While regular maintenance guarantees the operational readiness of your equipment, it's equally important to have a robust emergency response plan in place.

You'll need to conduct hazard identification and risk assessments, focusing on historical data, climate trends, and geographic vulnerabilities. This preparation enables you to craft detailed response plans for various emergencies, assigning clear roles and integrating communication protocols.

You should also establish a routine for emergency drills that enhance crisis management skills and guarantee every team member knows their responsibilities during an actual event.

Additionally, leveraging real-time data integration and utility mapping guarantees prompt identification and response to any unfolding crises, thereby minimizing potential damage and public inconvenience.

These strategies are essential for maintaining safety and operational continuity.

Integration of Quality Control Measures

To guarantee the success and safety of underground utility construction, integrating robust quality control measures is essential. Here are three crucial components to contemplate:

- Regular Performance Evaluations: Conduct functionality tests such as hydrostatic testing at specified pressures and utilize video inspections to monitor internal conditions of utility lines. This proactive approach guarantees that performance standards meet quality assurance criteria.

- Detailed Documentation and Mapping: Maintain meticulous records of utility locations and conditions during installations. This includes precise mapping using Quality Level A techniques for exact positional accuracy, essential for future accessibility and maintenance.

- Thorough Inspections and Monitoring: Implement frequent on-site inspections and advanced leak detection methods to identify and rectify issues promptly, thereby preventing future complications and guaranteeing long-term reliability of the infrastructure.

Encouragement of a Safety-First Culture

Encouraging a safety-first culture in underground utility construction not only enhances worker protection but also greatly reduces the risk of damaging existing infrastructure.

You'll want to foster this mindset through rigorous training and awareness programs. Regular toolbox talks and specific training on hazard recognition are essential. Assume every buried service is live until proven otherwise, and always mark utilities before digging begins.

Adherence to strict standards is non-negotiable. Follow OSHA's excavation protocols and utilize tools like IoT for continuous safety monitoring and Cable and Pipe Locating Devices to prevent utility strikes.

Safety incentives should be clear and compelling to motivate compliance.

Conclusion

To effectively mitigate risks in underground utility construction, you must prioritize thorough site assessments and employ advanced technologies like GPR and GIS mapping. Guarantee robust communication channels are in place and adopt stringent safety training. Regularly maintain and inspect your equipment, and have a clear emergency response strategy ready. By integrating quality control measures and fostering a safety-first culture, you'll greatly reduce accident risks, enhancing overall project success and safety.

If you're interested in learning more about how to enhance your underground utility construction practices, I invite you to visit Boring Bros at boringbro.com. You can also give us a call at (954) 639-6167. We're here to help and would love to share more insights with you!