You're entering a domain where innovative technologies like Ground Penetrating Radar (GPR) and GPS integration are essential in revolutionizing underground utility construction. With these tools, you can achieve unprecedented accuracy in mapping subsurface utilities, reducing the risk of costly damages and delays. Consider how the integration of robotics and trenchless technology could further streamline your operations, minimizing environmental impact while enhancing safety and efficiency. Imagine the possibilities as these technologies converge, transforming traditional practices and setting new industry standards. What next steps could you explore to integrate these advancements effectively in your projects?

Revolutionizing Detection With Ground Penetrating Radar

Ground Penetrating Radar (GPR) is transforming how professionals detect and map underground utilities. This radar technology, adept at identifying a diverse range of utility types including plastic, concrete, and metal pipes, is essential in utility mapping.

It not only locates operational lines but also unmasks abandoned utilities and undocumented connections, offering a detailed subsurface blueprint. GPR's non-invasive nature allows it to operate across multiple terrains without the need for excavation, adapting seamlessly to various soil conditions.

Real-time data collection and 3D imaging capabilities further enhance its effectiveness, providing precise, immediate visualizations of underground structures. This functionality guarantees thorough detection and mapping, vital for planning and risk management in underground utility construction. Additionally, GPR systems are equipped with self-calibrating antennas which automatically adjust to optimize performance in different soil types.

The Role of GPS in Enhancing Utility Mapping Accuracy

As you integrate GPS technology into utility mapping, you'll notice a substantial boost in the precision of your maps. This enhancement stems from the GPS's ability to work in tandem with other sophisticated detection technologies such as GPR and EM locators. The result is real-time, highly accurate data that greatly reduces errors and enhances the safety and efficiency of construction projects. Moreover, GPS technology facilitates continuous updates, ensuring that utility maps are always reflective of the current underground conditions.

GPS Integration Techniques

To enhance the accuracy of utility mapping, construction professionals are increasingly integrating GPS technology with other sophisticated tools such as ground-penetrating radar (GPR) and electromagnetic (EM) locating devices.

This integration greatly boosts utility tracking capabilities through:

- Enhanced Data Collection: GPS data, when combined with GPR and EM technologies, allows for rapid and precise data capture, updating location information within minutes.

- Optimized Project Layouts: Utilizing precise GPS utility mapping, you can avoid conflicts with existing infrastructure, enabling more innovative and efficient design solutions.

- Improved Safety Protocols: By accurately mapping utilities, the risk of accidental strikes during excavation drops, ensuring a safer environment for workers and the community.

This technology synergy propels underground utility construction into a new era of efficiency and safety.

Impact on Mapping Precision

When integrating GPS technology with ground-penetrating radar (GPR) and electromagnetic (EM) locating devices, the precision of underground utility mapping markedly increases.

You'll find that utility mapping innovations are revolutionizing how you address underground infrastructure challenges. With GPS, you're not just mapping; you're pinpointing utilities with formidable accuracy.

This integration facilitates real-time, precise data, drastically reducing errors and the associated high costs. It enables you to confidently plan and execute projects, guaranteeing they stay on schedule and within budget.

Additionally, this technology helps overcome the limitations of outdated records and rudimentary detection techniques by providing updated, real-time utility maps. This not only minimizes the risk of damaging existing infrastructure but also guarantees public safety and project efficiency.

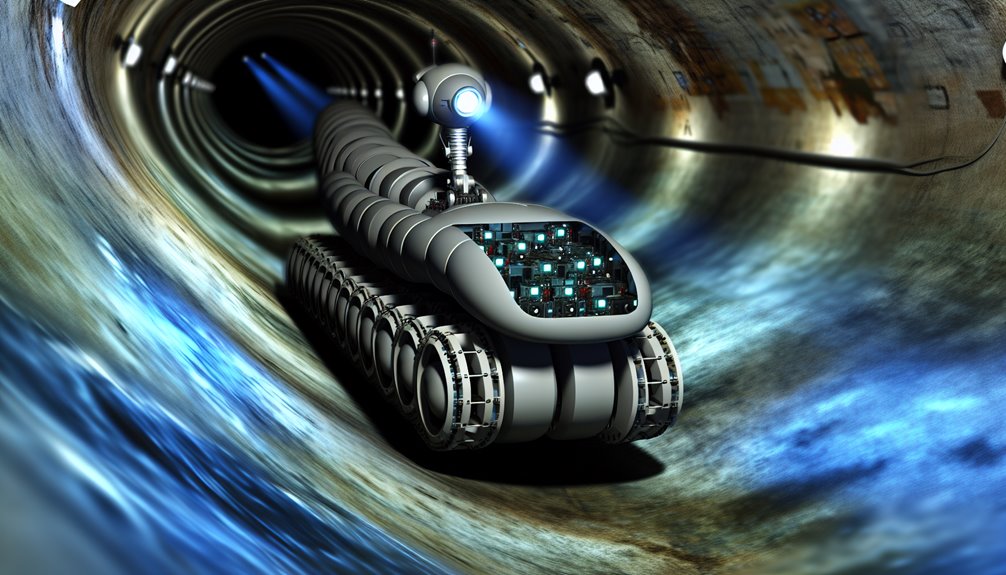

Robotics in Pipeline Inspection and Repair

You'll find that autonomous robots equipped with cutting-edge sensors and cameras are revolutionizing pipeline inspection and repair.

These robots can autonomously navigate through complex networks, identifying and documenting issues such as corrosion, blockages, and cracks with high precision.

In addition, their ability to perform on-the-spot repairs minimizes downtime and enhances overall pipeline integrity and operational efficiency.

Autonomous Robots in Action

Autonomous robots are revolutionizing the field of pipeline inspection and repair, enhancing operational efficiencies and safety.

You're at the forefront of this technological leap where robotic inspection and autonomous navigation merge, offering unprecedented capabilities in the maintenance of critical infrastructure.

Here's what you can expect:

- Safety: Robots perform hazardous tasks, drastically reducing human exposure to dangerous environments.

- Efficiency: Advanced sensors and cameras navigate and inspect pipelines with precision, minimizing downtime.

- Cost-effectiveness: Reduced risk and fewer disruptions translate into significant financial savings.

Equipped with cutting-edge technology, these robots navigate through harsh, inaccessible pipelines, providing high-definition images and real-time data.

This isn't just innovation; it's a transformative shift in how pipeline integrity is maintained.

Precision Pipeline Repair Techniques

As robotic technology advances, precision pipeline repair techniques continue to transform the underground utility construction industry.

Today's robotic advancements greatly enhance inspection efficiency. Equipped with high-definition cameras and multipoint data collection sensors, inspection robots deliver real-time monitoring and precise defect identification. These robots navigate seamlessly within various pipeline diameters, employing non-destructive testing (NDT) sensors like ultrasonic and electromagnetic technologies to detect anomalies and corrosion without halting pipeline operations.

Robots not only pinpoint the exact locations needing repair but also facilitate the precise placement of liners and execute both temporary and permanent repairs with minimal disruption.

This integration of diagnostic and repair capabilities guarantees cost-effectiveness, reduces downtime, and bolsters safety—heralding a new era of maintenance in critical infrastructure.

Trenchless Technology: A Leap in Installation and Maintenance

While traditional excavation methods have long dominated underground utility construction, trenchless technology represents a notable leap forward in both installation and maintenance processes.

You'll find the trenchless benefits compelling:

- Reduced Surface Disruption: Unlike open trench methods, trenchless techniques like Horizontal Directional Drilling and microtunneling allow for utility installations beneath busy roadways and rivers without major surface interruptions.

- Cost Efficiency: It greatly lowers the expenses associated with urban utility upgrades, particularly when crossing infrastructural barriers like railways and highways.

- Environmental Preservation: This method minimizes ecological footprint by maintaining soil integrity and reducing the need for large-scale excavation, thereby protecting natural habitats and landscaped areas.

Embrace these advanced installation techniques to enhance operational efficiency and reduce environmental impacts in your projects.

Utilizing AI for Data Analytics in Utility Management

Harnessing AI for data analytics in utility management transforms how we monitor, predict, and enhance performance across various systems. By integrating AI-powered predictive analytics, you're not just monitoring equipment health but proactively predicting failures, markedly reducing unplanned downtime and maintenance costs by up to 30%. This method guarantees the longevity of critical assets and minimizes service interruptions.

Furthermore, AI algorithms excel in analyzing patterns—from meteorological data to past usage trends—enabling precise energy forecasting and ideal load management. This results in balanced grid performance and efficient energy distribution.

Additionally, leveraging detailed customer insights, you can tailor services to individual energy usage, enhancing both customer satisfaction and engagement. AI's predictive capabilities empower you to anticipate and meet demands innovatively, assuring reliability and sustainability in utility management.

The Impact of Augmented Reality on Training and Operations

Augmented Reality (AR) is revolutionizing training and operations in underground utility construction, providing unprecedented precision and efficiency.

As you explore AR Training, consider these compelling benefits:

- Seamless Integration: Integrate AR with existing tools, enhancing your team's ability to manage projects with precision.

- User Empowerment: Equip your team with user-friendly AR interfaces, simplifying the learning curve and fostering swift Adoption Strategies.

- Continuous Support: Leverage ongoing technical support to guarantee flawless operation and adaptation to environmental challenges.

Conclusion

As you integrate these cutting-edge technologies, you'll witness a remarkable transformation in underground utility construction. GPR and GPS enhance your mapping precision, while robotics and trenchless methods streamline installation and repairs, reducing environmental impact. AI-driven data analytics optimize your utility management strategies, and AR tools elevate training and operational efficiency. Embrace these advancements to not only boost productivity but also to foster sustainability and collaborative excellence in your field.

If you're curious to learn more about these innovative technologies and how they can benefit your projects, I invite you to visit Boring Bros at boringbro.com. You can also give us a call at (954) 639-6167. We're here to help you explore these advancements and take your underground utility construction to the next level!