You've likely observed the shift in missile boring techniques, where operators have moved from rudimentary mechanical methods to advanced, digitally-enhanced processes. This evolution isn't just about faster drilling; it's about achieving pinpoint accuracy with minimal environmental footprint. By integrating GPS and GIS into their operations, contractors can now navigate complex underground terrains with unprecedented precision. As you consider the implications of these advancements, ponder how they not only streamline projects but also safeguard the surrounding ecosystems. Curious about the specific technologies involved?

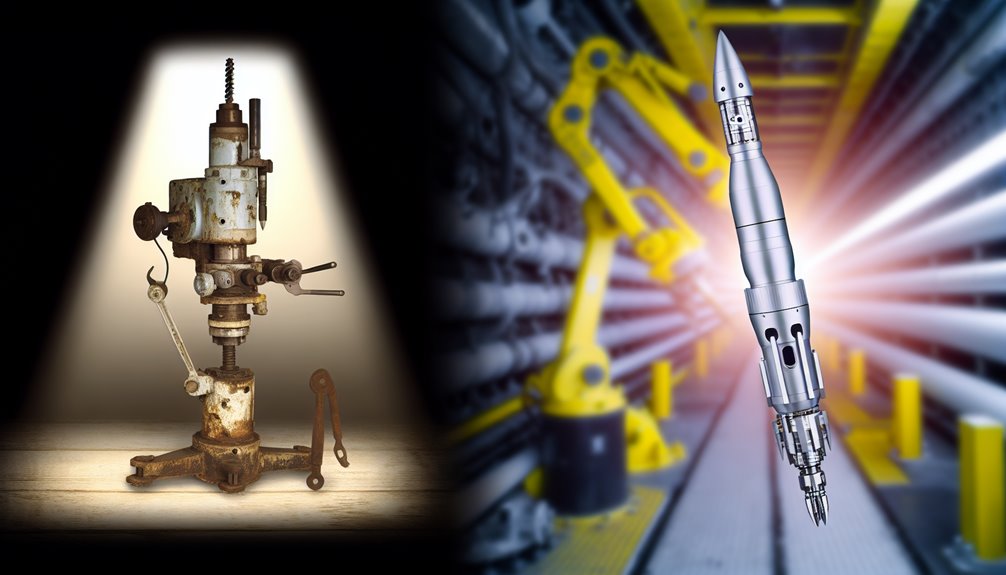

The Origins of Missile Boring: Early Techniques and Tools

While the concept of missile defense emerged during the final year of World War II in response to threats like the V-2 missile, early countermeasures were rudimentary, relying heavily on anti-aircraft guns. These initial measures reflected the technological limitations and the nascent understanding of missile threats. As you explore the early tools and historical methods of missile defense, it's pivotal to recognize the evolution from simple, unguided anti-aircraft artillery to more sophisticated tracking and interception technologies. This shift wasn't just a change in hardware but a fundamental rethinking of approach, driven by the urgent need for more effective defense mechanisms against increasingly sophisticated missiles. This historical perspective underscores the challenges and ingenuity in early missile defense efforts. Additionally, the development of theater missile defense systems, which focus on intercepting medium-range missiles, marked a significant advancement in the field, integrating radar and missile technology for greater precision and range.

Key Innovations in Missile Boring Equipment

Building on the historical methods of missile defense, contemporary missile boring technology has greatly advanced, incorporating robust pneumatic systems and trenchless methods. These advanced pneumatic systems utilize high-pressure air, controlled precisely by regulators to guarantee consistent operation. This setup not only allows the use of stingers or molds to streamline the boring process but also adapts to compact worksites, eliminating the need for large drilling rigs. Trenchless technology, on the other hand, facilitates the installation of vital utilities with minimal surface disruption, preserving infrastructure integrity. This method is particularly effective for embedding utilities like gas, water, and electrical conduits without the extensive excavation typically required, thereby enhancing operational efficiency and safety, essential in modern urban environments. Furthermore, the use of a trailer-mounted air compressor provides the high-pressure air necessary for the boring equipment's operation.

Integration of Digital Technology in Modern Boring Practices

As the field of missile boring evolves, the integration of digital technology has become pivotal, enhancing precision, safety, and efficiency.

You'll witness significant automation benefits as advanced drilling machines and GPS-assisted navigation systems minimize human error and maximize operational uptime.

Digital mapping, intertwined with GIS, affords you the capability to meticulously plan and execute bore paths, adapting in real-time to underground contingencies.

This digital overlay not only streamlines the workflow but also fortifies compliance with safety standards, utilizing digital monitoring to uphold stringent OSHA regulations.

Each of these advancements converges to bolster productivity, ensuring that project timelines are met with enhanced accuracy and reduced overhead, thereby setting new benchmarks in the industry's operational standards.

Case Studies: Successful Missile Boring Projects

To illustrate the effectiveness of modern missile boring techniques, consider several case studies that highlight the successful integration of advanced technologies and methods in complex environments.

In urban scenarios, you've seen the strategic deployment of horizontal directional drilling (HDD) to navigate beneath a hospital, ensuring minimal disruption while securing essential power line installations. This approach not only preserved the operational integrity of critical healthcare infrastructure but also demonstrated precision in maintaining urban life continuity.

For infrastructure resilience, projects involving directional drilling under waterways exemplify how missile applications adapt to environmental sensitivities. The use of HDD and auger boring achieved significant cost savings and enhanced project outcomes by minimizing ecological impact, showcasing a commitment to sustainable development practices in missile boring ventures.

Enhancing Safety and Precision in Missile Boring

Enhancing safety and precision in missile boring operations is essential for minimizing risks and guaranteeing high-quality outcomes.

You'll benefit from implementing thorough safety policies, including stringent drug screenings and robust insurance coverages. Regular safety audits, aligned with state and federal regulations, reinforce this framework.

Additionally, deploying precision techniques like surveying for ideal bore paths and using advanced tools such as reamers guarantees each phase of the boring process is executed with hawk-like accuracy.

Engage in daily safety practices, integrating Job Safety Analysis and Field Level Risk Assessment Tools to systematically identify and mitigate hazards.

Such meticulous attention to safety and precision not only enhances operational efficiency but also greatly reduces the likelihood of costly errors and accidents.

Environmental Considerations and Sustainable Practices

Building on the framework of safety and precision in missile boring, it's also essential to address environmental impacts and promote sustainable practices within the industry.

Horizontal Directional Drilling (HDD) projects minimize surface disruption, vital for protecting local ecosystems. You must guarantee drilling processes avoid the inadvertent returns (IRs) that could leak non-biodegradable drilling muds into the soil and groundwater, altering water chemistry.

Using sustainable materials, such as bentonite-based muds, requires meticulous management and disposal to avoid environmental harm.

Furthermore, implementing eco-friendly techniques that enhance energy efficiency, like those in Prairie Dog Boring Equipment, aligns with global sustainability goals.

Your commitment to these practices not only mitigates environmental impact but also sets a benchmark in the industry for operational excellence and compliance.

Future Trends and Potential Developments in Missile Boring Techniques

As missile boring continues to evolve, advancements in technology and equipment are setting new benchmarks for efficiency and cost-effectiveness in the construction sector.

You'll see a significant shift towards the integration of advanced materials and automated systems. These innovations promise to expand the capabilities of pneumatic boring, especially in overcoming limitations posed by soil conditions and hose length.

Anticipate the development of ultra-durable, flexible hoses that allow for extended ranges without requiring incremental stops. Additionally, automated systems equipped with AI will enhance precision surveying and path determination, minimizing human error and expediting the boring process.

These adaptations won't only reduce costs but also boost adaptability, making missile boring viable in previously challenging environments.

Conclusion

As you've seen, missile boring has undergone transformative changes, integrating digital technology like GPS and GIS for precision and adaptability. These advancements guarantee enhanced safety and sustainability, particularly in urban areas. By examining case studies, you've observed how these technologies facilitate successful, minimally invasive installations. Looking ahead, expect further innovations in equipment and techniques, continually improving efficiency and reducing environmental impact. Stay attuned to these developments to maintain cutting-edge practices in your projects.

If you're eager to dive deeper into the world of missile boring and discover how Boring Bros can assist with your projects, I invite you to visit us at boringbro.com. You can also reach out directly by calling (954) 639-6167. We're here to help and would love to chat about how we can support your needs!