As you explore the world of missile boring, consider the groundbreaking work achieved with the latest Tunnel Boring Machines (TBMs). These machines, equipped with precision-guided systems and AI-enhanced diagnostics, have tackled the formidable Rocky Mountains to establish secure missile installations. The integration of robotic arms and cutting-edge materials has not only sped up the process but also reduced the ecological footprint. To grasp the full scope of these technological marvels and their strategic implications, let's examine how they're reshaping defense infrastructure.

The Revolutionary Tunneling Technique That Changed Defense Infrastructure

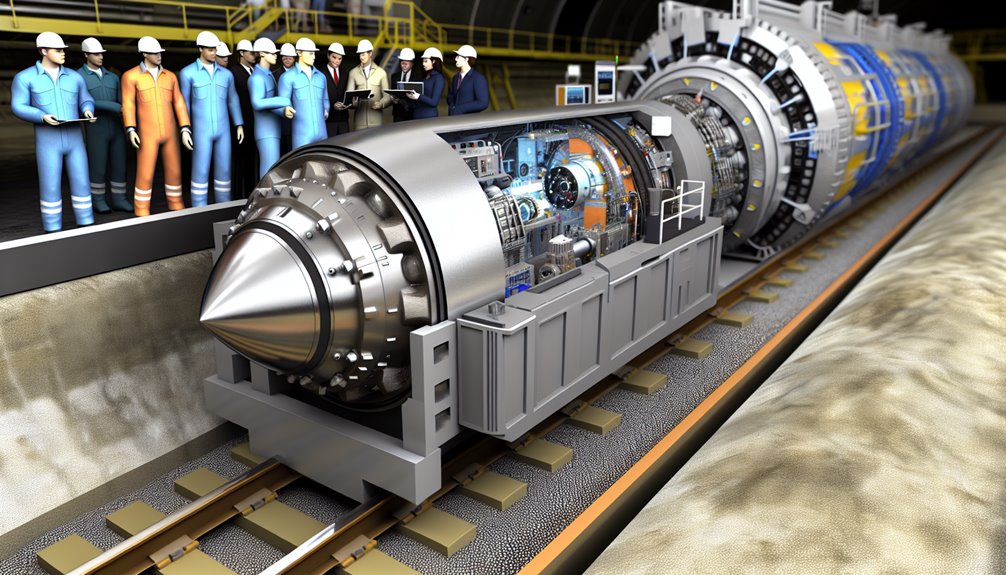

While traditional tunneling methods have long been a cornerstone of military engineering, the introduction of advanced Tunnel Boring Machines (TBMs) has radically transformed the landscape of defense infrastructure.

These machines have redefined tunnel warfare by enabling faster, safer, and more cost-effective construction of underground networks. TBMs aren't limited by ground conditions, which allows for the strategic deployment under diverse terrains.

With their integration, defense technologies have seen significant advancements, facilitating the creation of extensive and robust tunnel systems. These systems are essential for operations such as smuggling prevention, warfare logistics, and secure movement of troops and equipment.

The use of TBMs in military contexts underscores a pivotal shift towards more resilient and versatile defense capabilities. Notably, Hamas has employed tunnel-boring machines to enhance the sophistication and reach of their underground infrastructure, as seen in recent footage.

Overcoming Geological Challenges in the Rocky Mountains

As you tackle the geological challenges in the Rocky Mountains, employing advanced drilling techniques is critical. You'll need to leverage innovative material utilization, such as specialized polymeric additives for drilling fluids, to enhance the cutting efficiency and manage the diverse rock formations. These strategic approaches not only mitigate the harsh tunneling conditions but also optimize the project's operational timelines and budget. To ensure accuracy and fairness in reporting these innovative practices, it is crucial to adhere to responsible writing standards as outlined in "Writing Matters" by Rebecca Moore Howard, especially concerning the documentation of sources documentation of sources.

Advanced Drilling Techniques Employed

To tackle the formidable geological challenges presented by the Rocky Mountains, Missile Boring Contractors have deployed a suite of advanced drilling techniques.

You'll find that high-pressure air utilization and reciprocating action are central to their strategy. These innovative techniques guarantee that even under the hard, crystalline rocks typical of this region, the boring process remains precise and controlled.

By leveraging horizontal directional drilling (HDD) and auger boring, they adapt seamlessly to varied geological formations, from glacial deposits to dense crystalline structures.

This adaptability extends to their capability of handling diverse geology with minimal surface disruption, making advanced drilling not just effective but also environmentally considerate.

Innovative Material Utilization

Building on their repertoire of advanced drilling techniques, Missile Boring Contractors now leverage innovative material utilization to master the geological challenges of the Rocky Mountains.

You're employing materials with heightened durability and advanced composite advantages, capable of withstanding the intense geological stresses presented by granites, gneiss, and schists.

The strategic selection of robust tunnel boring machines and the implementation of specialized grouting techniques seal against highly saturated grounds.

Furthermore, the installation of advanced lagging and support systems effectively manages rock loads and prevents tunnel collapse.

Your continuous adaptation through real-time geological data guarantees the material choices constantly reflect the evolving underground conditions, thereby safeguarding your projects against unexpected geological surprises and associated cost overruns.

The Impact of Advanced AI on Missile Boring Accuracy

Precision in missile boring accuracy has seen transformative improvements with the integration of advanced AI technologies.

You're now traversing a landscape where AI-driven systems enhance precision but also present unique challenges such as AI limitations and the need for bias mitigation.

Here's how these technologies are reshaping your strategies:

- AI Limitations: Understanding that a 90% accuracy rate mightn't suffice in high-stakes scenarios necessitates continuous refinement of AI algorithms.

- Bias Mitigation: Implementing robust validation processes to prevent biases inherent in training data from skewing operational outcomes.

- Risk Assessment: Tailoring AI deployment strategies to the scale and risk profiles of operations guarantees reliability.

- Human Oversight: Integrating effective human-machine collaboration to balance AI capabilities with critical human judgment.

- Iterative Refinement: Employing customized evaluation frameworks to align AI performance with your precise missile boring objectives.

Integrating Green Technologies in Subterranean Excavations

As you integrate green technologies in your subterranean excavations, focusing on sustainable drilling methodologies not only preserves the local ecology but also enhances operational efficiency.

Utilizing eco-friendly materials reduces the carbon footprint associated with traditional construction materials, aligning with global environmental standards.

These practices not only guarantee regulatory compliance but also position your projects as leaders in sustainable development within the industry.

Sustainable Drilling Methodologies

While traditional mining approaches often face criticism for their environmental impact, sustainable drilling methodologies, integrating advanced green technologies, are reshaping subterranean excavations.

You're witnessing a revolution in mining where efficient extraction is harmonized with sustainable practices.

- Precision Drilling Techniques employ intelligent sensing systems, minimizing unnecessary excavation and focusing on ore, enhancing ore quality and reducing waste.

- Reduced Environmental Footprint through smaller surface disruptions and considerably lower emissions.

- Energy Efficiency sees a dramatic cut in consumption by over 50%, aligning with global energy conservation goals.

- Enhanced Safety Measures keep operations surface-based, mitigating underground hazards.

- Economic Advantages include lower operational costs and quicker access to ore, improving financial outcomes and reducing environmental costs.

Eco-Friendly Material Utilization

Integrating green technologies into subterranean excavations, the DRAGON project revolutionizes the way materials are handled and utilized, demonstrating a significant shift towards eco-friendly material utilization.

Employing automated systems like X-ray elemental analysis and microwave moisture measurement, the project guarantees precise characterization of excavated materials. This high-tech sorting mechanism, integrated directly into tunnel boring machines, facilitates in-stream sorting, drastically reducing waste and enhancing resource efficiency.

The project's zero waste strategy aligns with sustainable sourcing by recycling materials, thereby diminishing the need for primary mineral resources.

This approach not only cuts down EU dependency on imported materials but also propels transport efficiency within a 150 km radius, underscoring the project's commitment to eco-friendly practices and economic sustainability.

Breakthroughs in Long-Distance Underground Missile Sites

Recent advancements in long-distance underground missile sites have markedly altered the strategic landscape of modern warfare.

These facilities not only house missiles with enhanced range and precision but also bolster the strategic flexibility necessary for modern conflicts.

You're looking at a game-changer regarding operational security and global military balance.

- Enhanced Long Distance Capabilities: Extended range and precision of ship-targeting missiles.

- Strategic Flexibility: Ability to launch from secure, undisclosed locations.

- Reduced Vulnerability: Deep underground setting minimizes risk of enemy detection and attack.

- Advanced Communication Infrastructure: Integrated networks guarantee seamless command and control.

- Technological Integration: Utilization of AI and 5G technology to optimize missile system responsiveness and effectiveness.

Case Study: The Alaska Defense Tunnel Project

You're now examining the Alaska Defense Tunnel Project, where the scope and design reflect a profound commitment to integrating advanced permafrost engineering and military utility.

The project employs cutting-edge technological innovations, including a three-dimensional permafrost test bed, essential for both Earth and Mars polar research.

This initiative greatly bolsters regional security, providing a robust subterranean operations training platform while enhancing the strategic capabilities of the U.S. Army in extreme environments.

Project Scope and Design

While the Alaska Defense Tunnel Project at Fort Greely aimed to establish missile defense facilities, including five interceptor silos, it was constrained by the Anti-Ballistic Missile (ABM) Treaty, which limited the scope of testing and construction.

You're facing significant project management and design challenges, such as:

- Legal Constraints: Maneuvering through the ABM Treaty limited construction and testing capabilities.

- Safety Concerns: Proximity to populated areas restricted launch activities.

- Environmental Considerations: Compliance with environmental impact assessments delayed timelines.

- Radar Integration: Incorporating advanced radar systems like Cobra Dane required meticulous planning.

- Alternative Testing Sites: Utilizing existing facilities at Kwajalein and Vandenberg for intercept geometry tests, circumventing the need for local testing.

Each element needs strategic attention to innovate within imposed constraints.

Technological Innovations Employed

In tackling the Alaska Defense Tunnel Project, engineers implemented cutting-edge tunnel boring and excavation technologies to navigate the challenging subterranean conditions.

Advanced Tunnel Boring Machines (TBMs) adapted to various geological strata through real-time electrical resistivity imaging, enhancing tunneling technology by preemptively adjusting to impending shifts in ground conditions.

These TBMs, including specialized models for soft rock and hard rock applications, utilized hydraulic and rotary percussive drills, greatly boosting excavation efficiency.

In addition, the integration of roadheaders and the strategic use of drilling and blasting preserved critical permafrost areas, mitigating environmental impact.

Collectively, these innovations not only streamlined the excavation process but also minimized the risks associated with unpredictable geological changes, setting a benchmark in precision engineering and operational safety in extreme environments.

Impact on Regional Security

Given that the Alaska Defense Tunnel Project includes the Permafrost Tunnel Operations Facility, it directly addresses key national security concerns in the rapidly changing Arctic region.

You're seeing firsthand how enhanced capabilities in arctic engineering and strategic collaborations are pivotal for maintaining geopolitical stability and strengthening arctic security.

- Enhanced Military Readiness: Improved understanding and adaptation to permafrost changes bolster defense capabilities.

- Strategic Collaboration: Joint efforts between the U.S. Army Corps and ERDC optimize arctic operational strategies.

- Advanced Research Facilities: State-of-the-art infrastructure supports cutting-edge permafrost and arctic condition studies.

- Geopolitical Stability: Better preparedness and infrastructure resilience contribute to stable regional dynamics.

- Operational Preparedness: A focus on arctic-specific challenges guarantees readiness for emerging security scenarios.

Enhancing Safety Protocols in Missile Boring Operations

To enhance safety protocols in missile boring operations, it's imperative that contractors rigorously adhere to established safety standards throughout each phase of the project.

Cultivating a robust safety culture involves thorough risk assessments, ensuring that all personnel are proactive in identifying and mitigating potential hazards. Your pre-work planning must include critical analyses of both topside and subterranean risks, integrated into daily job safety analyses.

Regular safety audits and adherence to a meticulous work plan safeguard against unforeseen complications.

On-site, enforce stringent use of personal protective equipment and maintain two-way communication channels to manage operational contingencies effectively.

The Role of Robotics in Streamlining Tunnel Construction

While enhancing safety protocols in missile boring operations remains a pivotal concern, the integration of robotics within tunnel construction marks a notable advancement in the field.

You're witnessing a transformation where robotic efficiency and tunnel automation not only escalate productivity by 40% but also slash installation costs by 30%. These automated systems, embodying the pinnacle of innovation, tirelessly execute tasks, propelling projects toward unprecedented completion rates.

- Continuous Operation: Robots work non-stop, considerably boosting project speed.

- Safety First: Remote control and automation reduce human exposure to high-risk conditions.

- Precision Engineering: Advanced AI guarantees exact placement in complex tunnel geometries.

- Cost Reduction: Streamlined processes cut back on labor and operational expenses.

- Environmental Stewardship: Optimized material use and fewer machinery movements lower the carbon footprint.

Pioneering New Materials for Enhanced Boring Efficiency

As the tunneling industry evolves, missile boring contractors are increasingly turning to pioneering materials to enhance boring efficiency.

You'll find advanced materials like new metals and adaptive cutting technologies transforming the way tunnels are drilled. These innovations reduce the power needed, slashing operational costs and boosting sustainability.

Gas and plasma cutters stand out by minimizing mechanical resistance and torque, which speeds up the boring process notably—up to 100 times faster than traditional methods.

Additionally, integrating smart technologies, such as IoT sensors and automated controls, not only streamlines operations but also enhances safety by reducing human error.

Electric TBMs, leveraging renewable energy, particularly underscore the shift towards sustainable, high-efficiency tunnel construction, making them a cornerstone of modern tunneling strategies.

The Future of Missile Boring: Trends and Predictions

Building on the advancements in materials and cutting-edge technology that have revolutionized the efficiency of missile boring, the sector now stands on the brink of several transformative trends and predictions that will shape its future.

- AI and Automation: Enhanced integration of AI in drilling operations predicts increased precision and efficiency, addressing future challenges in complex geological conditions.

- Sustainability Drives: Electrification and the use of renewable energy in boring operations are set to become standard, minimizing environmental impact.

- Advanced Propulsion Systems: The adoption of hypersonic and reusable missile technologies will redefine propulsion norms.

- Regulatory Influence: Market dynamics will increasingly be influenced by international compliance and environmental regulations.

- Strategic Market Shifts: Expect more mergers and strategic alliances, reshaping the competitive landscape and fostering technological advancements.

Conclusion

As you explore the advanced domain of missile boring, it's clear that integrating AI, robotics, and green technologies isn't just innovative; it's vital. These breakthroughs not only enhance precision and efficiency but also guarantee environmental stewardship and safety. The future beckons with trends towards more resilient materials and smarter systems, promising even greater achievements in defense infrastructure. Stay ahead by leveraging these developments, making certain your projects not only meet but exceed the stringent demands of modern military needs.

If you're curious to learn more about how we can help you stay at the forefront of missile boring technology, I invite you to visit Boring Bros at boringbro.com. You can also give us a call at (954) 639-6167. We're here to assist you and would love to discuss how our innovative solutions can fit your needs!