You’ve heard directional drilling is just “digging sideways,” but you’re managing 3D steering with MWD/LWD, gyro surveys, rotary steerables, and tight tolerances—often <1% of measured depth. Accuracy hinges on survey control, QA/QC, and real-time corrections, not guesswork. Costs swing with geology, tool selection, and depth, while closed-loop fluids and waste recycling manage impacts. If you’re planning utilities, geothermal, or crossings near live lines, the real questions start with risk, permits, and provider proof.

What Directional Drilling Is and How It Differs From Vertical Methods

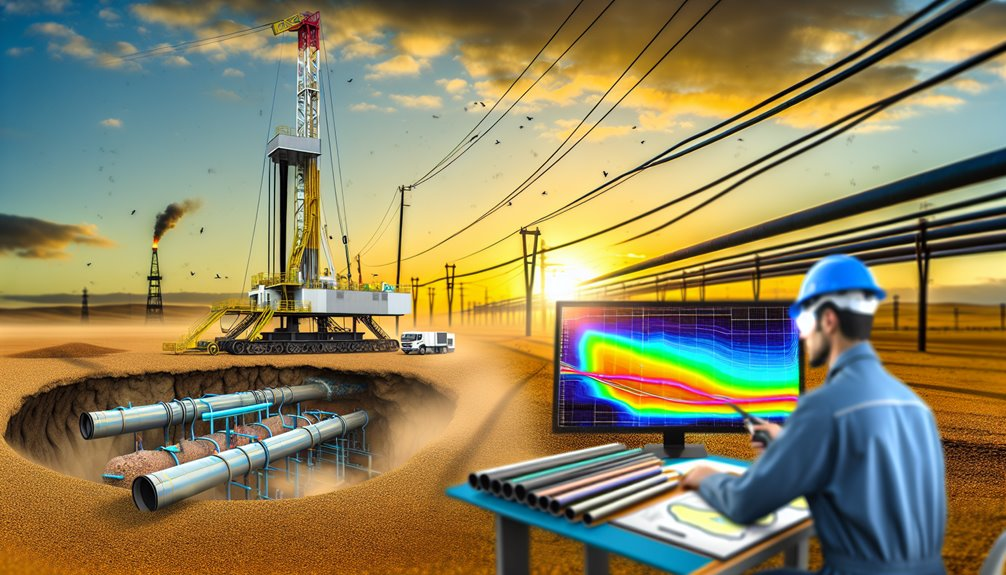

Although the term sounds broad, directional drilling specifically refers to intentionally steering a wellbore along a planned three-dimensional trajectory rather than drilling straight down. You design that path to hit targets, avoid hazards, and maximize contact with productive zones. Unlike vertical methods, you manage inclination and azimuth continuously, using trajectory planning to control dogleg severity, tortuosity, and build/hold/drop sections within geomechanical limits.

You rely on directional surveying to quantify position and uncertainty, integrating MWD/LWD data to correct course before errors compound. You’ll model torque-and-drag, hydraulics, and anti-collision envelopes so offsets stay safe and drillstring loads remain within specs. The payoff is tighter surface footprints, fewer pads, and higher recovery from laterals and multizone access. In short, you proactively navigate the reservoir; vertical drilling simply penetrates it.

Key Components and Steps in the Drilling Process

Start with a well plan that ties geology, trajectory, and equipment to clear performance limits, then execute with the right hardware and controls. You’ll kick off with a surface hole, set casing, and verify pressure integrity.

Build angle using a mud motor and stabilizers, stiffened by drill collars for weight on bit and directional response. Manage hydraulics, bit selection, and flowrates to control ROP and cuttings transport. Track torque, drag, and vibration, adjusting weight and RPM before dysfunction cascades. Condition mud for density, rheology, and inhibition so the hole stays stable and data stays clean.

- Rig up efficiently; test every safety barrier

- Calibrate MWD/LWD before drilling ahead

- Program slide/rotate sequences

- Monitor ECD and cuttings returns

- Trip, ream, sweep, and cement methodically

Accuracy, Steering Technology, and Tolerances You Can Expect

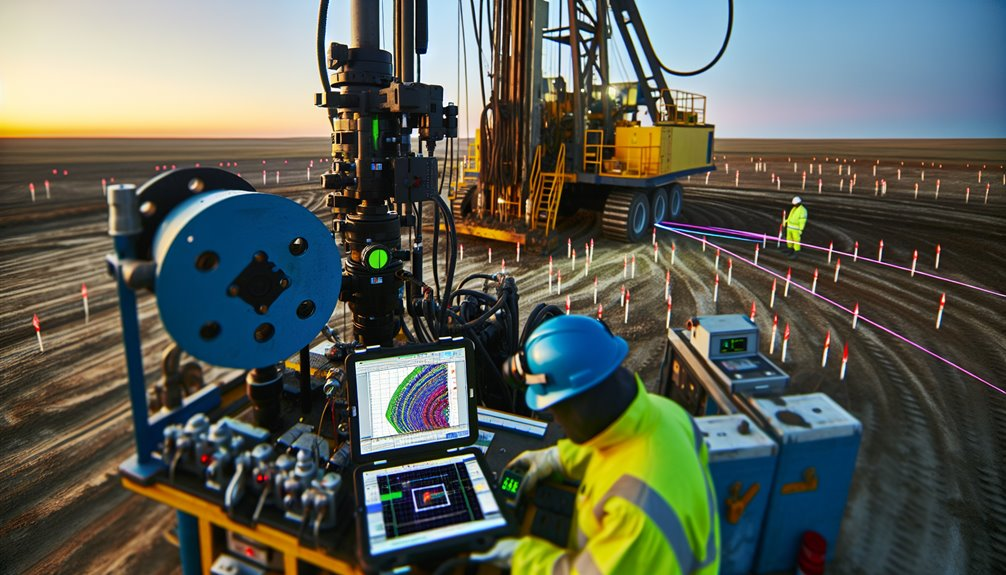

When you plan directional accuracy, tie expected toolface control and survey uncertainty to the well’s positional tolerance and collision risk. You’ll anchor decisions in survey accuracy: understand MWD error models, inclination/azimuth noise, and how magnetic interference shifts the ellipse of uncertainty. Execute rigorous toolface calibration on surface and in-hole; verify sag and bias on bottom.

Use downhole sensors—triaxial magnetometers, gyros, and continuous inclination—to validate trend and detect drift. Apply real time corrections: adjust slide/rotate ratios, weight transfer, and motor yield to hold course. With modern rotary steerables, expect 0.2–0.5° DLS fidelity and sub-5 m TVD error in the curve, tightening laterally to plan limits in hold.

Document tolerances, anti-collision scans, and stop-go criteria so your team steers confidently together.

Applications Beyond Oil and Gas: Utilities, Geothermal, and More

Those same steering tolerances and survey controls pay off outside hydrocarbons, where you’ll thread bores through congested corridors and tight thermal targets. You’ll use HDD to place urban utilities—fiber, power, water, and district energy—beneath paved rights-of-way with centimeter-scale positional certainty.

In geothermal retrofits, you’ll land laterals into compact collector fields, hit heat-exchanger depths, and minimize thermal short-circuiting with accurate spacing. Microtunneling-scale radii let you bypass rivers, rail, and historic zones while preserving surface use. Data from downhole MWD and gyro surveys verifies as-builts for asset registries and future tie-ins.

- Replace failing mains without trenching neighborhoods

- Add high-count fiber under built corridors with minimal disruption

- Drill geothermal laterals aligned to thermal models

- Cross sensitive corridors with engineered radii

- Deliver repeatable, survey-grade locations for long-term integrity

Safety Practices and Risk Management Near Existing Infrastructure

Although directional drilling can thread bores with centimeter accuracy, safety near live utilities depends on disciplined controls, not confidence. You validate every alignment with multi-source locating: as-built records, utility sweeps (EM, GPR), and potholing to expose conflict points. Establish exclusion zones and enforce proximity monitoring with calibrated walkover systems, track-on receivers, and gyroscopic confirmation in congested corridors.

Before pulling pipe, you run a pre-job hazard analysis, lock in strike alerts, and define stop-work thresholds (e.g., loss of depth, signal distortion, torque spikes). You document pressure, RPM, and pullback limits, then log them in real time for variance alarms. You brief joint crews daily, integrate municipal permits, and maintain community engagement to synchronize windows, traffic control, and shutdown contingencies. After action, you audit deviations and update utility maps.

Environmental Considerations: Surface Impact, Fluids, and Waste

Even as you dial in bore accuracy, your environmental footprint hinges on how you manage surface disturbance, drilling fluids, and waste streams. You minimize pad size, segregate topsoil, and schedule around sensitive windows.

Track fluid losses with mass-balance; a 2–3% unaccounted variance flags inadvertent returns. Use bentonite blends tuned for formation permeability and recycle with high-G centrifuges to cut disposal volumes by 60–80%.

Implement runoff management with berms, silt fence, and stabilized entrances to keep turbidity below permit thresholds. Containerize cuttings, profile waste, and manifest to approved facilities.

Close with surface reclamation: regrade, de-compact, replace topsoil, seed natives, and verify with photo points and vegetation cover data.

- Protect wetlands with matting and buffer setbacks

- Use closed-loop fluid systems

- Calibrate returns monitoring

- Deploy spill kits and drills

- Document reclamation and compliance logs

Cost Drivers, Budget Ranges, and When It Saves Money

When you budget a directional bore, you pay for risk, rate of penetration, and hole quality. Your big cost drivers are geology (hardness, abrasivity, heterogeneity), measured depth, build/turn severity, mud program, tool selection (MWD/LWD, rotary steerables), rig class, and contingency for stuck pipe or lost circulation.

You manage drilling economics by matching tools to rock, optimizing WOB, RPM, and hydraulics, and keeping tortuosity low to reduce friction and later intervention costs.

Expect budget ranges to scale from modest per-foot rates in soft formations to multiples in interbedded or high-angle wells. Track cost/ft, ROP consistency, NPT percentages, and reaming time.

Directional drilling saves money when it shortens surface access, avoids crossings, hits multi-target pads, and lowers lifecycle costs through smoother wells, fewer repairs, and longer asset uptime.

Timeline Basics: Planning, Permitting, and Execution Windows

Before you mobilize a rig, build a realistic timeline that sequences engineering, surveys, permits, procurement, and construction with critical-path discipline.

Anchor milestone dates to field realities: geotech lead times, utility locates, rig availability, and seasonal access.

Apply permit sequencing early so approvals align with procurement and crew windows.

Protect the path with schedule buffers at design freeze, material delivery, and pre-bore verification.

You’ll cut idle time, avoid rework, and build trust across the team.

- Lock scoping assumptions with survey-grade data and geotech logs.

- Map permit sequencing to long-lead materials and subcontractor awards.

- Time procurement to HDD rig schedules and fluid system capacity.

- Insert schedule buffers for weather, contingencies, and inspection slots.

- Stage execution windows around environmental and traffic constraints.

Regulatory Requirements, Easements, and Compliance Essentials

Although each jurisdiction layers its own rules on top of federal statutes, you’ll only de‑risk an HDD crossing if you treat regulatory compliance, land rights, and environmental stewardship as an integrated workstream from day one.

Map the right of way with title evidence, survey control, and encumbrance checks; verify easement width, depth restrictions, and restoration obligations.

Align your bore path with utility locates and environmental buffers, then sequence approvals: NEPA/state equivalents, waterbody crossings, cultural resources, traffic control, and discharge authorizations.

Track permit renewals and seasonal windows in a shared register with lead times and dependencies.

Document frac-out response plans, drilling fluid composition, and waste manifests.

Audit adherence with field checklists and as-built data.

Communicate transparently with landowners and regulators to sustain trust.

Choosing Providers: Capabilities, Experience, and Quality Indicators

Because the wrong contractor can turn a routine HDD into a risk register, vet providers by the work they’ve executed, the geology they’ve mastered, and the metrics they track. Ask for bore logs, pullback loads, annular pressures, frac-out incidents, and schedule adherence.

Confirm they manage mud rheology, tooling selection, and steering corrections with documented procedures. You’ll want a firm with calibrated rigs, verifiable QC, and transparent change management—not just a logo.

- Proven HDDs in your soil types, with as-built data and verifiable KPIs

- In-house or audited workforce training; NCCER/API credentials, TRIR trends

- Fleet depth and equipment leasing strategies to mitigate downtime risks

- Subsurface intelligence: utility mapping, walkovers, gyro/ParaTrack, risk registers

- Quality indicators: tool calibration records, drilling fluid labs, daily ITPs

Choose partners who share lessons learned and own the outcome.

Conclusion

So there you have it — directional drilling isn’t some mysterious “sideways digging,” it’s precise 3D navigation done with tight survey control, calibrated MWD/LWD and gyro QC, motor/RSS steering, and real‑time verification guided by error models rather than luck. We manage utility risk with potholing, strike alerts, frac‑out plans and closed‑loop fluids, and we budget and schedule based on geology, depth and tool class while vetting providers by their QA/QC, training and compliance history. If you want to chat more about how we do it at Boring Bros, visit boringbro.com or give me a call at (954) 639-6167 — I’d love to talk through your project and find the best, safest solution for you.