You’re planning work in Georgia’s fast-changing corridors, and utility strikes aren’t an option. GPR gives you decision-grade subsurface intelligence—detecting metallic and non-metallic lines, resolving depths and vertical separations, and exposing abandoned assets EM misses. With calibrated, multi-frequency surveys, RTK control, and dense grids, you get georeferenced, confidence-coded models that protect crews, schedules, and budgets. But Georgia’s soils, aging infrastructure, and mixed corridors demand more than a checkbox approach—here’s what it takes to do it right.

Why Georgia’s Growth Demands Advanced Utility Locating

As Georgia accelerates infrastructure, industrial, and residential development, accurate subsurface intelligence becomes nonnegotiable. You’re delivering on tight schedules amid population expansion, utility congestion, and evolving right-of-way constraints. One errant excavation triggers outages, claims, and schedule slippage that ripple across stakeholders. Advanced utility locating provides the decision-grade certainty you need to coordinate trades, sequence work, and limit rework.

You’re managing infrastructure strain on aging corridors while tying in new service laterals, duct banks, and drainage. Legacy as-builts, variable soil conditions, and undocumented abandonments escalate risk. High-resolution utility mapping, integrated with survey control and GIS, lets you validate clearances, design around conflicts, and set enforceable dig tolerances. When you standardize on advanced methods, you reduce utility strikes, protect public safety, and keep Georgia’s growth moving without disruption.

How GPR Works to Detect Metallic and Non-Metallic Utilities

While metal detectors only respond to conductive targets, ground-penetrating radar (GPR) images both metallic and non-metallic utilities by transmitting high-frequency electromagnetic pulses into the subsurface and analyzing the reflected waveforms. You read the returns as changes in dielectric contrast between soil and a target. Metallic pipes generate strong, polarity-consistent reflections; plastics, fiber, and concrete produce subtler hyperbolas that still stand out when the soil’s permittivity is well characterized.

You select antenna frequency to balance penetration and depth resolution: higher frequencies sharpen utility tops and joint features; lower frequencies reach deeper corridors. You also calibrate velocities using known depths or on-site hyperbola fitting to convert two-way travel time into accurate elevation. Proper stacking, filtering, and migration clean clutter, isolate utilities, and maintain positional confidence across Georgia’s varied soils.

Comparing GPR to Traditional Locating Methods

Though metal detectors and electromagnetic (EM) locators remain useful for conductive lines, GPR gives you a broader, utility-agnostic view that captures both metallic and non-metallic assets, depth profiles, and subsurface context. When you rely solely on electromagnetic induction, you’re limited to energized or tracer-wire-equipped utilities and vulnerable to signal coupling, congestion, and ghosting. GPR’s radar reflections resolve pipe geometry, bedding, and adjacent features, improving pipe mapping where data density and ground truth matter.

You also gain vertical separation data instead of just a surface trace, enabling tighter confidence intervals on depth and alignment. In Georgia’s variable soils—clays, fills, and cobbles—you’ll adapt by tuning antenna frequency and survey grids, integrating EM marks with radargrams. That blended workflow strengthens decisions, field productivity, and shared trust across your team.

Mitigating Risk: Preventing Service Outages, Fines, and Delays

Dial in GPR early to cut strike risk, keep services online, and stay ahead of penalties and schedule creep. You reduce unknowns before equipment mobilizes, verifying depths, alignments, and conflicts with high-resolution subsurface data. That clarity lets you redesign trench routes, adjust bore paths, and sequence work to avoid costly rework and service disruptions.

Use marked grids, depth slices, and time-stamped logs to lock in accountability and satisfy audit trails. By pairing GPR with utility maps and 811 tickets, you validate records, catch abandoned lines, and confirm clearances at crossings. You’ll prevent line hits that trigger regulatory penalties, liquidated damages, and emergency restorations. Tight tolerances and documented locates keep inspectors confident, crews coordinated, and stakeholders aligned—so your schedule holds, your budget stays intact, and your reputation earns trust.

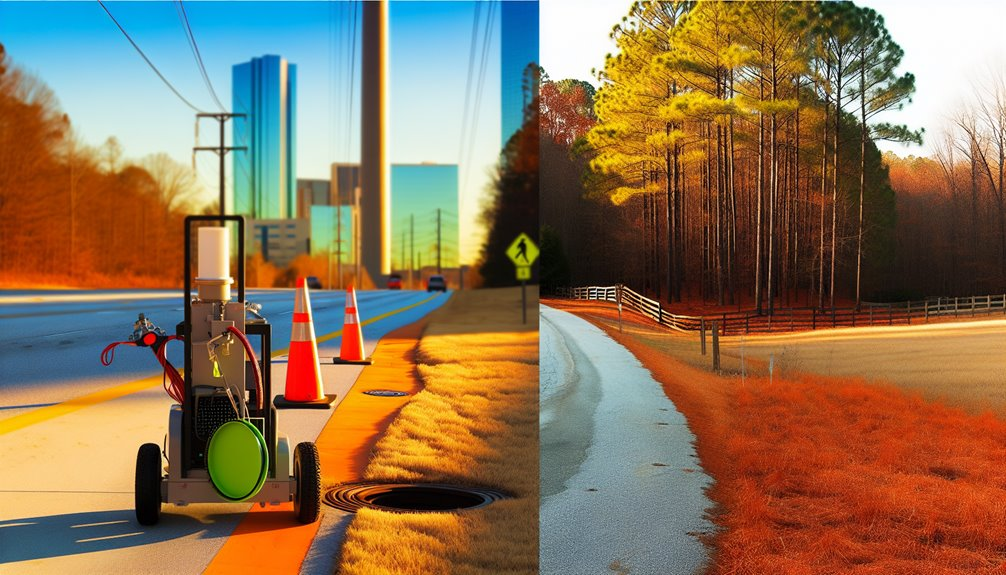

Urban vs. Rural Applications Across Georgia

Even as Georgia’s geology stays consistent, urban cores like Atlanta and Savannah demand a different GPR approach than rural corridors and agricultural tracts. In cities, you navigate tight easements, utility congestion, and signal noise from rebar, conduits, and traffic infrastructure. You’ll favor higher-frequency antennas for near-surface resolution, dense grids, and meticulous mark-outs to separate overlapping signatures in Dense suburbs.

Rural deployments let you widen line spacing and run longer transects for pipeline, telecom, and drainage mapping. You’ll often select lower-frequency antennas for deeper penetration and pair GPS with RTK corrections for accurate corridor records.

Along Coastal marshes, you mitigate saline attenuation, saturated soils, and soft ground by optimizing gain, stacking, and coupling, and by staging access platforms. Across settings, disciplined QA/QC keeps your interpretations defensible.

Dealing With Variable Soils and Aging Infrastructure

Urban or rural, your GPR workflow in Georgia meets a harder problem set when variable soils intersect with aging utilities.

You manage soil variability first: Piedmont clays attenuate high frequencies, while Coastal Plain sands scatter less but hide shallow fines; mountain gravels create clutter. You adapt by selecting antenna frequencies per target depth, running orthogonal grids, and calibrating velocity with hyperbola fits and on-site dielectric checks.

You also account for infrastructure aging: corroded metallics reduce continuous reflections, spalled concrete shifts rebar spacing, and degraded joints create false terminations. You mitigate by tightening line spacing, logging amplitude decay, and verifying targets with multiple polarizations.

You document uncertainties, mark confidence levels, and brief crews so everyone operates from shared, defensible interpretations.

Integrating GPR With 811, EM Locating, and Survey Data

While 811 tickets and as-built plans establish the legal and historical baseline, you integrate them with EM locating and GPR to build a reconciled, field-verifiable model.

You align survey control, georeference marks, and run structured passes to reduce ambiguity. Then you apply data fusion to correlate EM responses, GPR hyperbolas, and mapped elevations, flagging conflicts for ground-truthing. With machine learning classifiers, you prioritize likely utilities versus clutter, but you still verify with potholing and as-built updates.

- Calibrate: tie GPR/EM to survey benchmarks, project datum, and time-synced logs.

- Correlate: overlay 811, plans, EM peaks, and GPR slices to resolve depth/phase.

- Validate: probe anomalies, refine targets, and record QA photos.

- Deliver: export a GIS/CAD utility model, confidence-coded and traceable.

Project Types That Benefit Most From GPR Locating

With a reconciled, field-verified utility model in hand, you can target GPR where it delivers the highest risk reduction and value. Dense urban infill, hospital campuses, universities, and airports benefit most—complex subsurface congestion demands non-invasive confirmation before sawcuts or bore shots.

Roadway widening, bridge replacements, and roundabout retrofits gain utility conflict clarity without lane closures. For historic renovations, GPR preserves fabric while mapping unknown services beneath fragile slabs and courtyards.

Industrial turnarounds and plant expansions use GPR to verify private utilities, process lines, and abandoned conduits. Solar farms, EV charging, and data center builds de-risk trenching across greenfields.

Parks, sports complexes, and landscape irrigation upgrades avoid shallow strikes. Finally, multifamily and mixed‑use redevelopments tighten schedules by validating as-builts prior to excavation.

Choosing a Qualified GPR Provider in Georgia

Because GPR results drive safety and design decisions, you need a provider in Georgia with proven subsurface utility engineering (SUE) credentials, not just a scanner. You’re selecting a partner who’ll protect crews, schedules, and budgets. Verify their methodology, documentation standards, and ability to integrate findings into your CAD, BIM, and survey control.

- Confirm credentials: demand SUE experience, certified technicians, and calibration records for multi-frequency antennas and ancillary EM tools.

- Require process transparency: pre-survey utility research, QA/QC checklists, georeferenced deliverables, and stamped reports where applicable.

- Validate risk controls: insurance verification, safety program metrics, confined-space and traffic-control qualifications, and incident-free references.

- Assess capability fit: urban noise mitigation, clay/karst adaptations, GPS/RTK accuracy, and rapid mobilization statewide.

Choose a team that understands Georgia soils, DOT expectations, and your field’s standards.

Conclusion

When it comes to keeping projects on time and crews safe across Georgia — from busy city streets to coastal corridors and rural builds — I don’t leave anything to chance. At Boring Bros, we use calibrated, multi-frequency GPR with RTK control, dense grids, and EM correlation to produce georeferenced, confidence-rated models that help you avoid outages, fines, and costly delays. I’d love to talk about how we can support your next job — visit boringbro.com to learn more or give me a call at (954) 639-6167.