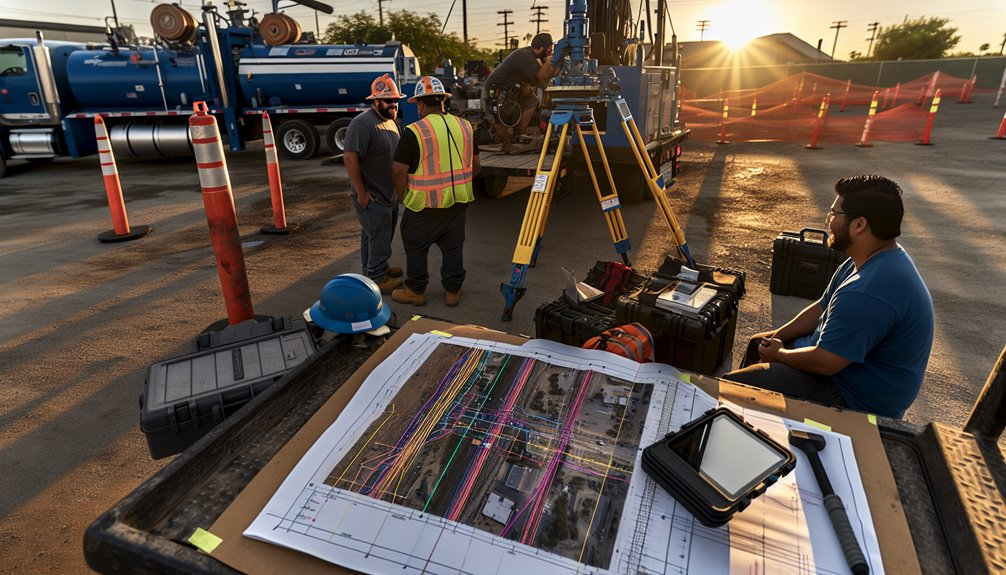

Before you break ground on HDD, you need a disciplined checklist that verifies utility locates with positive ID, confirms geotech data tied to hold points, and locks bore-path tolerances. You’ll also need permits in hand, a fluid plan with closed‑loop containment, calibrated tracking, and defined roles with stop‑work authority. Add traffic control, environmental protections, and an actionable EAP. Miss one element, and you accept avoidable risk—so what should be validated first?

Verify Utility Locates and Positive Identification

Before mobilizing, confirm all utility locates are current, complete, and documented per state 811 requirements and company procedures. You verify ticket numbers, response codes, and expiration dates, then perform utility markings confirmation against approved plans.

Validate color codes, offsets, and depths provided by owners; reconcile conflicts immediately. Require competent-person oversight and keep as-built utility records onsite.

Execute pothole verification using non-destructive methods to positively identify facility type, size, depth, and alignment at all crossings and minimum-clearance points. Record measurements, photos, and GPS references; have owners or locators witness when feasible.

Establish hold points: no drilling until positive identification is achieved and clearances meet project standards. Communicate findings in the tailboard, update the bore plan, and flag any variance for engineering review and owner notification.

Assess Geotechnical Conditions and Ground Stability

With utilities positively identified and clearances verified, shift your focus to subsurface risks that control bore safety and performance. You’ll anchor decisions in geotechnical data, not assumptions.

Commission soil testing per ASTM/ISO: classify soils, measure shear strength, plasticity, density, and moisture; identify cobbles, voids, collapsible or swelling layers, and cemented horizons. Log groundwater depth and variability; plan dewatering and drilling fluid density to counter hydrostatic uplift and frac-out.

Evaluate stability at entry/exit pits and along work zones. Perform slope monitoring and settlement surveys near structures, using inclinometers or prisms where risk warrants. Map hazards from historical fills and karst.

Document bearing capacity, liquefaction potential, and erosion susceptibility. Align tooling, fluid rheology, and contingency controls with the characterized ground so the whole crew operates confidently and consistently.

Finalize Bore Path Design and Tolerance Limits

Although geotechnical and utility constraints set the envelope, you now lock in a bore path that satisfies clearance, curvature, and stress limits with explicit tolerances.

Define entry/exit angles, minimum radius from pipe specs, and maximum bore curvature by soil modulus and product stiffness.

Calculate overpull/mud pressure envelopes, then set positional tolerances for depth and lateral offset at each station.

Use gyro or wireline survey control and pre-approve tie-in checks for tolerance verification.

Model annular pressure to avoid frac-out and verify allowable bend strain, ovality, and joint stress under buoyancy control.

Document exclusion zones around utilities with hard no-go offsets.

Establish hold points for design change review.

Share the finalized plan, drawings, and QA checklists so your crew aligns to the same limits.

Confirm Permits, Notifications, and Regulatory Compliance

Your finalized bore path and tolerances only work if the job stands on firm regulatory ground, so verify every permit, notification, and condition precedent before mobilizing.

Map each authority having jurisdiction, then align permit timelines with your schedule float and critical path.

Confirm crossing approvals, ROW consents, environmental clearances, traffic control plans, and after-hours variances.

Document one-call tickets, utility owner notifications, and special conditions in a controlled register.

Cross-check license scope against tasking—equipment, trenchless method, depths, and durations.

Validate insurance, bonding, and erosion controls match permit stipulations.

Pre-stage compliance evidence for regulatory audits and client QA.

Establish hold points: no staging, excavation, or pilot until written authorization is on file.

Brief the crew so everyone knows the limits, triggers, and contacts.

Plan Drilling Fluid Program and Containment Strategy

Before rigs roll, engineer a drilling fluid program that’s geotech-specific, standards-based, and containment-led.

Specify rheology, density, and filtration targets from soil borings; choose additives aligned with API/ASTM guidance and environmental permits.

Define mix procedures, on-site testing frequency, and decision thresholds for losses, returns, and inadvertent returns.

Design closed-loop circulation with right-sized mud recycling to minimize haul-off and water demand.

Pre-plan containment berms, lined pits, and secondary containment around tanks and transfer points; verify capacities exceed worst-case surge volumes.

Map fracture-risk zones, annular pressure limits, and pilot-to-reaming adjustments.

Establish spill response steps, materials, and roles, including vacuum recovery and disposal manifests compliant with local regulations.

Train crews on sampling, logkeeping, and communication triggers, so the whole team owns fluid stewardship.

Inspect Rig, Tooling, and Tracking Equipment

With the fluid program and containment plan defined, verify the iron that will execute it.

Conduct a documented rig inspection per OEM specs and ANSI/ASSP standards.

Check frame integrity, mast pins, guards, interlocks, and emergency stops.

Confirm hydraulic pressures, pump output, and rod makeup torque meet tolerance.

Inspect drill string, subs, and swivels for wear, cracks, and thread damage; gauge and reface as required.

Validate tracking calibration and beacon batteries before pilot.

- Inspect mud pumps, hoses, and valves; pressure-test to rated working pressure with certificates.

- Verify strike alert, rotation limits, and pullback indicators function under load.

- Measure rod OD/ID, tool joint taper, and shoulder flatness; record results.

- Confirm beacon frequency, depth accuracy, and interference testing.

- Check locating receiver firmware, antennas, and spare components readiness.

Establish Communication Protocols and Roles

Although equipment readiness reduces mechanical risk, you still need disciplined, unambiguous communication to control the bore. Define stakeholder responsibilities before mobilization: designate a site safety lead, drill operator-in-charge, tracker lead, mud engineer, and utility liaison. Document who speaks, who confirms, and who records. Standardize call-and-response phrases for steering, pressure, flow, and shutdown. Use dedicated channels and hand signals with positive confirmation; prohibit dual meanings.

Run a pre-bore briefing and periodic check-ins. Log setpoints, deviations, and authorizations. Establish escalation procedures with thresholds: inadvertent returns, loss of returns, strike indicators, frac-out risk, and LOC/LOTO conflicts trigger immediate stop-work and chain-of-command notification. Test radios, backups, and fail-silent rules. Train alternates to maintain continuity. Close with a post-shift debrief to capture lessons and update the plan.

Set Up Traffic Control and Site Access

Clear communication only works if people and equipment can move safely. You implement traffic control to ANSI/ISEA 107 and MUTCD guidance, integrating lane management, detours, and flagging plans. Define protected haul routes, turning radii, and exclusion zones around drill strings, vac trucks, and spoil handling. Place access signage at decision points so crews, deliveries, and the public know where to enter, queue, or stay out. Coordinate permits with the road authority and verify sight distances day and night.

- Engineer a lane management plan with taper lengths, buffer zones, and positive protection.

- Deploy certified flaggers with two-way redundancy.

- Post access signage: gate IDs, PPE requirements, speed limits, and escort rules.

- Separate pedestrian, plant, and public interfaces.

- Audit setups daily and after any phase change.

Implement Environmental Protections and Spill Response

Start by hard-bounding your work footprint and runoff pathways before a bit turns. Install silt fence, wattles, and berms per SWPPP and local stormwater permits. Stage secondary spill containment under fuel, lubricants, and drilling fluid totes; keep absorbents and boom within 50 feet of mixing, pumps, and generators. Verify double-walled tanks, drip pans, and intact hoses. Pre-locate wetlands and waterbodies; set exclusion buffers and timing windows for wildlife protection, nesting, and migration.

Pressure-test the mud system; log volumes, viscosity, and return rates to detect inadvertent returns early. Use non-toxic fluid additives where practicable. Place frac-out response kits at water crossings; pre-plan access routes that avoid riparian damage. Segregate waste streams; label and manifest properly. Document inspections, remedial actions, and regulatory notifications to close compliance loops.

Conduct Pre-Job Briefing and Emergency Action Plan

Before iron moves, conduct a formal pre-job briefing that aligns with your company’s HSE management system, OSHA 1926, and API RP 100-1/100-2. Define pre job roles, risk controls, and stop-work authority so everyone knows their lane and your thresholds. Validate equipment condition, permit readiness, and utility locates. You’re building a team that owns the plan and the response.

- Confirm task scope, bore path, geotech data, and strike potential.

- Assign pre job roles: drill lead, mud engineer, locator, safety watch, communications.

- Review emergency contacts, site address, access routes, clinic/hospital, and ICS structure.

- Drill emergency actions: strike, fluid loss, entrapment, fire, severe weather, and evacuation.

- Verify communications: primary/backup radios, hand signals, call tree, and accountability.

Document attendance, deviations, and approvals.

Conclusion

I’m proud of the work we do at Boring Bros., and safety is how we protect our people, your project, and our reputation. If you’d like to dive deeper into any of these checks or see how we put them into practice, visit boringbro.com or give me a call at (954) 639-6167 — I’m happy to answer questions and walk you through our process.