You can bypass tree roots and sensitive landscapes with trenchless auger boring by mapping root zones, staging pits outside driplines, and steering a cased bore below critical depths. Specify casing, cutting head, and tolerance to ASTM/EN standards, and set vibration and heave thresholds with stop‑work triggers. Use sealed spoil handling to prevent contamination. Coordinate with an ISA‑certified arborist and define restoration specs up front. Here’s how to plan and execute it without guesswork.

Why Trenchless Auger Boring Protects Surface Features

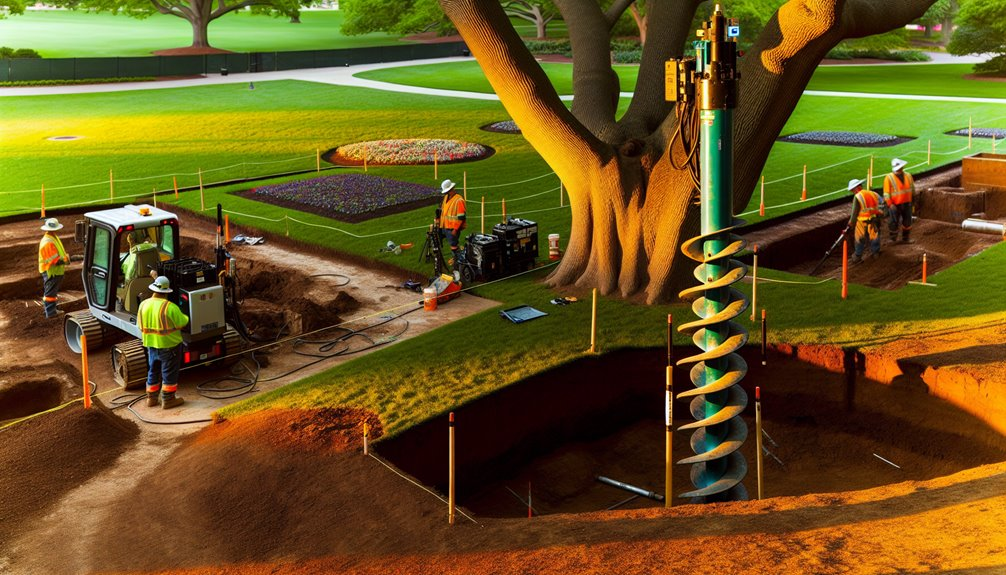

From the outset, trenchless auger boring minimizes surface disruption because it advances a casing and rotating auger entirely below grade, eliminating open-cut excavation across lawns, hardscapes, and root zones.

You stage pits outside protected areas, maintain line and grade with surveyed controls, and contain spoils within the casing to prevent surface heave.

By specifying thrust loads, jacking pressures, and annular clearances per industry standards, you reduce settlement and avoid undermining pavements.

You also integrate root mapping to position launch and reception pits away from sensitive features and align the bore path through suitable soils.

Canopy protection planning informs equipment height, access routes, and exclusion zones, so you don’t compact soils or damage branches.

With precondition surveys, vibration limits, and daily QA logs, your team safeguards surfaces and community expectations.

Understanding Tree Root Zones and Critical Root Areas

Although roots can extend well beyond the canopy, you should treat the Tree Protection Zone (TPZ) and Critical Root Zone (CRZ) as the primary constraints for bore planning. The TPZ protects the broader absorptive network; the CRZ safeguards structural roots essential for stability. Define both per local standards (e.g., diameter-at-breast-height multipliers) and verify in the field.

Use root mapping to locate major laterals, buttress roots, and voids. Combine non-invasive tools (air spade exposure, ground-penetrating radar) to refine depth and orientation. Keep allowable disturbance within specified thresholds: limit excavation within the CRZ and control vibration, dewatering, and spoil loads.

When conflicts are unavoidable, specify arborist-led root pruning with clean cuts, timing, and aftercare. Document protective fencing, load-spread mats, and monitoring to maintain compliance and shared stewardship.

Planning a Bore Path Around Mature Canopies

Before staking the alignment, integrate arborist data and utility constraints to plot a bore path that skirts the TPZ and entirely avoids the CRZ of each mature tree. Use canopy mapping to translate crown spread into setback buffers, then add variance for lean, slope, and expected growth. Tie offsets to root protection fencing and reference them on plan and profile sheets, so every crew member reads the same limits.

Sequence your approach and exit pits outside dripline projections, adjusting clearances for microclimate factors—prevailing wind, heat loads, and irrigation patterns affect stress tolerance. Lock in seasonal timing to minimize transpiration stress and compaction risk. Calibrate curvature and depth to keep annular pressures low near roots. Document hold points, approval steps, and stop‑work triggers everyone can stand behind.

Soil Investigation and Risk Assessment Before Drilling

With the bore path staked to respect TPZ and CRZ limits, you now verify subsurface conditions that govern auger selection, torque, thrust, and allowable annular pressures.

Perform soil borings along the alignment to classify strata, identify groundwater, and flag cobbles or obstructions.

Log blow counts, plasticity, and moisture; correlate to settlement risk and face stability.

Execute contaminant testing where legacy fill or utilities suggest exposure risks, and plan handling per ASTM and local environmental codes.

- Confirm groundwater elevation, seasonal variance, and potential inflows that could destabilize the face.

- Map discontinuities—fills, lenses, and voids—so you can stage mitigation and monitoring.

- Establish trigger levels for vibration, settlement, and turbidity; align them with arborist protection plans.

Document findings, update your risk register, and brief the whole crew before mobilization.

Choosing the Right Diameter, Casing, and Cutting Head

Start by sizing the bore to the minimum functional diameter that meets capacity, clearance, and maintenance needs while preserving TPZ/CRZ offsets. Use diameter selection tables tied to pipe OD, joint envelopes, and annulus control. Keep overcut tight to limit voids and root exposure.

Choose casing that resists buckling and ovality; verify wall thickness against jacking loads, soil arching, and groundwater. Maintain casing alignment with calibrated lasers and frequent station checks to avoid TPZ encroachment. Seal joints to prevent slurry migration into root zones.

Match cutting head to mapped strata. For clays, use open-face heads with adjustable spoil relief; for gravels, pick reinforced head materials and carbide tooling to stabilize cutting performance. Balance rotational speed and thrust to prevent surge, heave, and settlement.

Guided Boring Techniques for Precision Alignment

Although auger methods can drift under variable soils and root deflections, you can hold line and grade by integrating a pilot-guided system and formal QA controls.

Start with a precisely surveyed baseline, then run a pilot bore using steerable tooling and laser guidance to control azimuth and elevation within tolerance.

Validate the bore path continuously with target readings and compare to your control file.

Document variances, apply minor course corrections, and lock alignment before upsizing.

- Use laser guidance with calibrated offsets; confirm target visibility and refraction factors.

- Specify steerable tooling with articulated heads; verify response to incremental jacking inputs.

- Implement QA checkpoints at set chainages; record grade, line, and deviation trends.

Entry and Exit Pit Placement to Minimize Disturbance

Dial in entry and exit pit locations to protect roots, utilities, and finished surfaces while meeting line-and-grade and safe access requirements.

Begin with a utility locate and root-zone mapping; set pits outside critical root zones and drip lines, and maintain clearance from trunk flares.

Verify setback, spoil staging, and truck access without loading softscapes.

Align pits to minimize bore length, maintain thrust block capacity, and keep cutterhead recovery within property limits.

Size pits to OSHA shoring standards, dewater if needed, and plan egress routes that don’t traverse fragile turf.

Schedule around seasonal timing to avoid saturated soils and peak sap flow.

Maintain pit aesthetics with tight footprints, clean edges, geotextile underlay, and matting.

Document approvals, barricades, and restoration tolerances the whole crew can own.

Monitoring, Spoil Management, and Vibration Control

Routinely instrument the bore with line-and-grade checks, head pressure/torque logs, and audible/visual monitoring to detect drift, obstructions, and root contact in real time.

You’ll align to spec when you verify as-built against design at defined footage intervals. Use real time monitoring to trigger corrective actions—reduce thrust, adjust rotation, or pause to clear spoil—before minor deviations cascade.

Manage spoil with sealed conveyance, staged screening, and spoil dewatering to control moisture, mass, and haul-off compliance.

Maintain pit sumps and filter socks to prevent fines migration. Document volumes for traceability.

Control vibration by setting allowable particle velocity limits, calibrating sensors, and adjusting advance rate and cutter configuration to stay below thresholds.

- Verify line/grade every 10–20 feet

- Log torque/pressure trends each rod

- Track PPV and frequency continuously

Coordinating With Arborists and Landscape Designers

Why coordinate early with arborists and landscape designers? You align boring alignment, depths, and staging with root-protection zones before conflicts surface.

Schedule an arborist consultation to map structural roots (using ISA and ANSI A300 guidance) and classify tolerance by species, age, and season. Share your bore profile, casing OD, thrust, and slurry or spoil-handling plan so they can flag high-risk crossings and acceptable clearances.

Use landscape phasing to sequence access, mats, and staging so loads avoid critical root areas and irrigation lines remain serviceable. Co-develop a cut/no-cut protocol, tolerance bands for deviation, and stop-work triggers tied to root encounters or vibration thresholds from your monitoring plan. Document roles, communication cadence, and submittals. When you coordinate, you protect assets, reduce rework, and keep the team aligned.

Post-Bore Restoration and Long-Term Tree Health Checks

Closing the bore doesn’t end your obligations—you move on to restoration and monitoring guided by ISA Best Management Practices and ANSI A300.

Backfill launch pits with structured soil, restore mulch rings, and verify drainage paths so oxygen and water reach feeder roots.

Protect trunks and soil with decompaction where needed, then document baselines for future comparison.

- Verify root health with resistograph or air-spade exposure at select points; photograph and geotag findings.

- Schedule seasonal inspections to track canopy density, shoot extension, leaf chlorosis, and soil moisture trends.

- Implement nutrient supplementation only after soil and foliar diagnostics confirm deficiencies, avoiding salt injury.

Calibrate irrigation to evapotranspiration, not guesswork.

Flag any girdling roots or fungal conks for arborist evaluation.

Share data with stakeholders, align rechecks to warranty periods, and adjust prescriptions as conditions evolve.

Conclusion

As the owner of Boring Bros., I stand behind every job we do to protect roots and finishes by treating auger boring as a controlled, standards-based operation. We define CRZ/TPZ limits, select diameter and casing to maintain cover, and stage pits outside driplines. We validate soils, set vibration and settlement thresholds, and enforce stop-work triggers. We use sealed spoil conveyance and steering logs to keep tolerances tight, coordinate with arborists, document conformance, and restore pits with structured soils and decompaction. Finally, we perform post-bore inspections and monitoring to verify tree health and landscape performance. If you’d like to learn more, please visit boringbro.com or give us a call at (954) 639-6167 — we’d love to talk about your project.