When you use horizontal directional drilling for municipal water and gas upgrades, you avoid open cuts, maintain traffic, and protect sensitive corridors. You steer precisely with verified subsurface data, monitor annular pressure to prevent frac-outs, and stage rigs to minimize footprint. Vacuum excavation exposes conflicts safely. Standardized testing, chlorination, and purging streamline commissioning. With coordinated permits, outreach, and traffic control, you cut risk and downtime—yet the real advantages show up when capacity needs to increase under tight constraints.

Minimizing Surface Disruption in Dense Urban Corridors

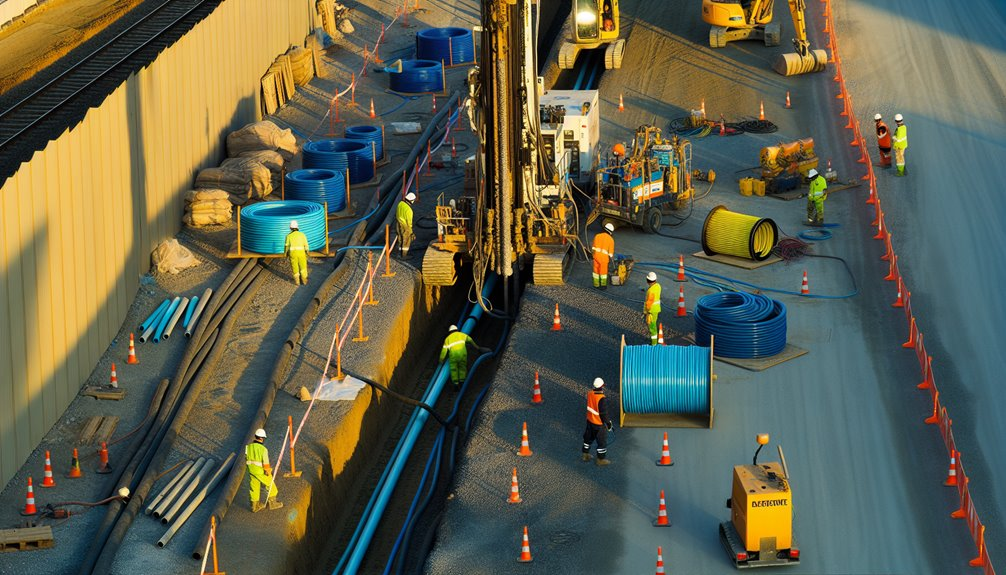

In dense urban corridors, horizontal directional drilling (HDD) lets you install or replace water and gas mains while keeping streets open, utilities online, and surface assets intact.

You stage compact rigs, use vacuum excavation for daylighting, and steer beneath pavements, rails, and critical crossings with compliant depth-of-cover.

You’ll validate alignments with utility locates, ASCE 38 QL-B/C records, and pre-ream to a diameter matching pipe and annular fluid management.

HDD minimizes trench length, limits temporary traffic impacts to small work zones, and protects tree roots, slabs, and streetscapes.

You’ll manage permit coordination across agencies, specify drilling fluids with low-loss additives, and implement frac-out response plans.

QA/QC includes pullback monitoring, pressure logging, and post-install pressure tests per AWWA and ASTM.

Accelerating Project Timelines and Reducing Downtime

Building on minimized surface disruption, HDD also compresses schedules and limits service outages by sequencing utility locates, geotech, and design to enable same-day pilot bores and staged pre-reams. You drive schedule optimization by front-loading subsurface data, validating drill paths, and kitting tools so crews mobilize once and progress continuously. With tight stakeholder coordination, you align traffic control, inspector availability, and shutoff windows, then fuse and pull pipe during low-demand periods to shorten outage durations.

You’ll standardize cut sheets, mud programs, and pullback QA to eliminate rework. Real-time telemetry confirms bore progress, letting you pre-stage tie-ins and pressure testing. By batching crossings and using reusable pits, you reduce setup cycles. The result is predictable durations, faster service restoration, and a team rhythm everyone can trust.

Protecting Existing Utilities With Precision Trenchless Paths

From pothole to pullback, you protect existing plant by engineering drill paths that maintain code-clearances, respect utility strike tolerances, and stay within verified geotechnical windows.

You start with utility mapping that blends record research, EM locates, GPR, and daylighting to confirm line depth, material, and condition.

You design bores with calculated bend radii, annular pressure limits, and separation factors specified by AWWA, API, and CSA standards.

You model ground vibration and hydrofracture risk, then set steering tolerances and correction points before staking the corridor.

During pilot, you track with dual-frequency walkover or wireline, validate depth with potholes, and adjust vectors proactively.

You log as-built data, verify separations, and document clearances so everyone on the corridor knows the plant stayed protected.

Enhancing Safety for Crews and the Public

While HDD minimizes open-cut exposure, you still manage significant risk to crews and the public by codifying controls that align with OSHA, CSA, and local right-of-way requirements. You validate job plans with stamped traffic control, signed utility locates, and documented crew training tied to task-specific competencies.

You brief stakeholders through targeted public outreach and keep neighbors informed with clear access routes, noise windows, and emergency contacts. You verify fluid management, strike avoidance, and egress plans before tooling rotates.

- Establish a written SH&E plan: hazard analysis, permit matrices, Stop Work authority, and daily tailboards.

- Implement competency-based crew training with verifiable qualifications and drill-specific refreshers.

- Execute public outreach: door tags, 811 coordination, hotline, and signage with multilingual messaging.

- Monitor in real time: annular pressure, gas detection, frac-out logs, and exclusion zone compliance.

Cost Efficiencies Compared to Open-Cut Methods

Beyond minimizing surface disruption, horizontal directional drilling (HDD) reduces total installed cost by compressing schedule, labor, and restoration line items that drive open-cut overruns. You eliminate repeated trenching mobilizations, shrink traffic control windows, and avoid premium pavement and landscaping reinstatement. Crews place longer pipe strings in a single shot, driving labor savings while maintaining spec compliance.

HDD also supports predictable budgets. You lock in bore length, product diameter, and pull forces upfront through geotech, drill plan, and ASTM/ASCE-aligned submittals, reducing change orders. Fewer utility conflicts mean fewer standby charges and less contingency burn. When you apply lifecycle costing, HDD’s corrosion protection, fewer joints, and minimal surface cuts lower future leak response and resurfacing costs. The result is a shorter critical path, tighter cost variance, and a program your team can stand behind.

Navigating Complex Crossings: Roads, Rivers, and Rail

Although every corridor poses its own constraints, HDD excels at threading new mains beneath highways, navigable waterways, and active rail without open-cut shutdowns by anchoring design to geotech, utility records, and governing standards. You translate constraints into drill paths: define allowable curvature, confirm cover, and select mud programs that stabilize formations and control returns at roads, river crossings, and rail interfaces.

You validate separation from foreign lines, verify bore windows, and coordinate flagging, track protection, and encroachment permits.

- Profile right: run swept-radius designs, entry/exit pads, and hydrofracture checks tied to soil strength.

- Proveability: log-as-built with gyro and intersect methods for QA/QC.

- Protection: specify casing, spacers, and insulation near rail and bridge foundations.

- Continuity: stage pipe strings, pressure test, and commission within traffic and navigation curfews.

Environmental Benefits and Landscape Preservation

Because HDD installs mains from controlled entry/exit pads with underground tooling, you minimize surface disturbance, preserve root zones, and protect habitats while meeting agency thresholds for turbidity, noise, and emissions.

You stage rigs on stabilized pads, use biodegradable drilling fluid, and monitor returns to comply with SWPPP and BMPs.

Frac-out response plans, silt curtains, and upland containment keep waterways clear.

You sequence bores to avoid nesting windows and coordinate with arborists for tree preservation, applying air-spade potholing and trunk/critical root zone fencing.

You document spoils handling, dewatering, and noise control with calibrated meters, demonstrating adherence to local ordinances.

Post-bore, you restore contours, decompact access paths, seed with native mixes, and implement habitat restoration.

Your team reduces truck trips, limits idling, and verifies benefits through third-party inspections and as-built environmental closeout reports.

Upgrading Capacity to Meet Regulatory Compliance

When regulators tighten fire flow, peak-hour demand, or MAOP requirements, you can use HDD to upsize mains and services without disrupting built environments while meeting code.

You replace undersized lines with larger, pressure-rated pipe while maintaining separation, cover, and joint integrity.

With capacity modeling, you validate diameters, velocities, and pressures before drilling, aligning upgrades with regulatory timelines and community expectations.

- Verify code-driven parameters: fire flow at hydrants, peak-hour headloss, and MAOP with documented safety factors and qualified materials.

- Select pipe and coatings compatible with HDD pullback forces, bend radii, and tracer/locator requirements for post-install verification.

- Stage bypass service to sustain customers and critical facilities during cutover without violating permit conditions.

- Commission lines: pressure test, disinfect or purge, sample, and submit records to demonstrate compliance.

Planning, Mapping, and Risk Management Best Practices

Before you set a drill head, build a defensible plan that integrates geotechnical data, utility maps, and permit constraints into a single, version-controlled basis of design. Start with a desktop study, then verify in the field: pothole critical crossings, log boreholes, and calibrate soil parameters to your mud program. Use route optimization to minimize bends, high-risk geology, and third-party assets while maintaining hydraulic and code requirements. Formalize stakeholder engagement early—public works, utilities, traffic control, and adjacent property owners—and record decisions and constraints.

Map the bore path with survey-grade control, specify allowable tolerances, and define strike-avoidance protocols, stop-work triggers, and contingency alignments. Run a quantified risk register: likelihood, consequence, mitigation owner, and closeout criteria. Document as-builts promptly to sustain institutional memory.

Case Scenarios for Water and Gas Main Replacements

Across typical corridors, you’ll face repeatable HDD scenarios for replacing aging water and gas mains: a constrained urban arterial with dense utilities and traffic staging; a creek or rail crossing requiring long-radius arcs, settlement control, and environmental windows; and a residential collector with short shots, numerous service tie-ins, and variable legacy records.

You validate bore paths with potholing, steering logs, and as-built reconciliation, then confirm hydraulics with flow modelling and integrity with pressure testing. You standardize on proven rigs, reamers, drilling fluids, and annular pressure limits to protect adjacent assets and maintain level-of-service.

- Urban arterial: night shifts, vacuum spoil control, simultaneous detours.

- Creek/rail: anti-buoyancy, scour checks, frac-out monitoring.

- Residential: service reinstatement sequencing and meter changeovers.

- Commissioning: swab, disinfect, pressure testing, and SCADA cutover.

Conclusion

At Boring Bros, I’m proud that we use HDD to upgrade water and gas mains with minimal disruption, faster schedules, and strict risk control. By combining precise subsurface mapping, steerable bores, annular-pressure monitoring, and vacuum excavation, we protect existing utilities and the public while meeting codes through standardized commissioning, pressure testing, and clear documentation. We plan for every contingency—frac-out responses, coordinated permits, and thoughtful traffic staging—so you save time, reduce costs, and lower environmental impact while upsizing capacity for compliance. If you’d like to learn more or talk through a project, please visit boringbro.com or give us a call at (954) 639-6167 — I’d be happy to help.