As you explore the latest advancements in missile boring contractor services, you'll notice a significant shift towards integrating AI to enhance design accuracy and precision. This evolution not only streamlines operations but also minimizes human error, paving the way for safer and more efficient drilling projects. By employing advanced algorithms, contractors now achieve pinpoint accuracy in trajectory planning and real-time adjustments. Consider how these technological upgrades could redefine your project's scope and execution, urging a closer look at the potential impacts on cost and time efficiency.

The Rise of AI in Missile Boring: Enhancing Design and Precision

As the defense industry embraces technological advancements, the integration of Artificial Intelligence (AI) in missile boring processes is revolutionizing both design and precision. You're witnessing a significant shift where AI optimization plays an essential role in enhancing the accuracy and efficiency of missile construction. By employing precision engineering techniques, AI algorithms analyze vast datasets to optimize drilling parameters, minimizing human error and maximizing output quality. This approach not only speeds up the production cycle but also guarantees that each component meets stringent performance criteria vital for defense applications. As AI continues to evolve, its ability to adapt and refine boring processes in real-time promises to set new standards in missile technology, making systems more reliable and effective in critical scenarios. The integration of the Orchestrike AI system with the SPEAR missile family highlights a significant advancement in missile technology, ensuring enhanced coordination and mission performance.

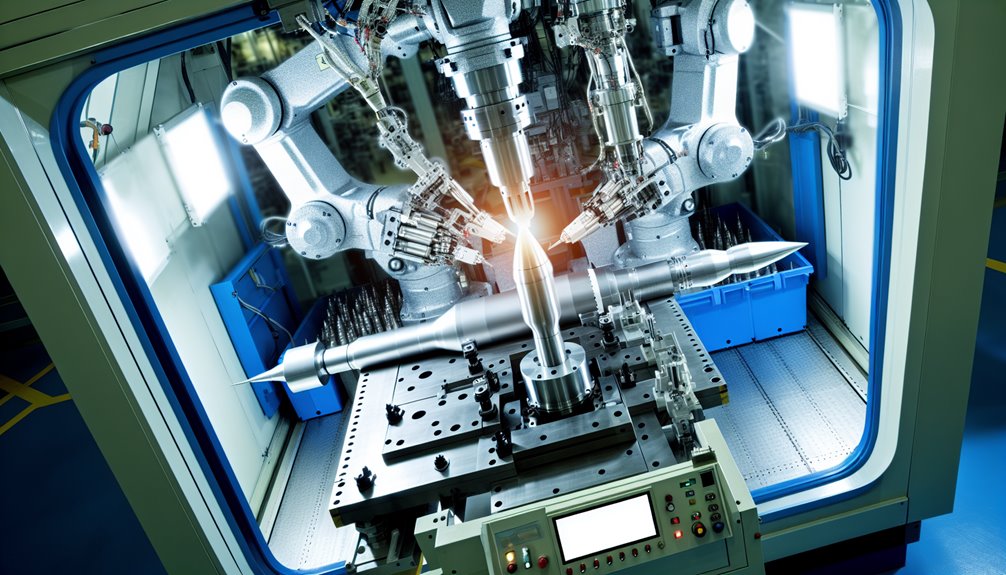

Robotic Automation in Drilling: A Leap Towards Safer Operations

While exploring the intersection of safety and efficiency, robotic automation in drilling emerges as a vital advancement.

You'll find that automated drilling systems, like NASA's "borebots," are essential for executing high-precision tasks in hazardous environments, greatly enhancing robotic safety. This not only minimizes human error—a key factor in workplace accidents—but also adheres strictly to safety standards, elevating compliance.

Moreover, the integration of these robots with existing machinery boosts overall operational efficiency. Robotic systems can also be equipped to handle missile boring techniques, enhancing precision in sub-surface installations.

Automation benefits are clear: they reduce labor intensity and protect workflows from interruptions related to human safety issues, ensuring continuous operation.

This leap in technology not only mitigates risks but also reshapes your expectations of safety and efficiency in drilling operations.

Advanced Materials for Enhanced Durability and Performance

Building on the foundation laid by robotic automation in drilling, the focus now shifts to the materials used in these operations, which play a pivotal role in enhancing durability and performance.

Polyethylene, particularly HDPE, offers significant benefits due to its corrosion resistance, making it ideal for water and gas lines.

Steel, with its robust applications, excels in high-pressure environments, ensuring longevity under significant external loads.

Fiber reinforcement in polymers and coatings enhances structural integrity, drastically improving load-bearing capabilities and resistance to environmental stressors.

The integration of advanced coating technologies, such as epoxy and polyurethane, further fortifies these materials against corrosion and mechanical damage, extending the operational life of drilling infrastructure.

The Role of 3D Printing in Customizing Missile Boring Equipment

3D printing revolutionizes the customization of missile boring equipment by enabling the creation of highly specialized components tailored to unique operational requirements.

This technology facilitates the production of complex designs and intricate geometries that traditional methods can't achieve. You'll find that 3D printing applications considerably reduce lead times, allowing for rapid prototyping and immediate adjustments in custom equipment designs.

The integration of exotic materials enhances the microstructure and overall performance of missile components. Furthermore, hybrid applications that combine additive and subtractive manufacturing techniques meet stringent quality and durability standards.

However, the challenge remains in achieving consistent quality for on-demand field production, necessitating ongoing advancements in process reliability and material optimization.

Real-Time Data Analytics for Improved Decision Making

As you integrate advanced analytics tools into your operations, you'll find that these technologies enhance decision-making by processing and visualizing data in real-time.

This data-driven strategy not only refines your operational tactics but also elevates overall project management through precise performance monitoring techniques.

Emphasizing these aspects guarantees you're not just keeping pace but setting the benchmark in missile boring efficiency and safety.

Advanced Analytics Tools

In the rapidly evolving field of missile boring contractor services, advanced analytics tools play a pivotal role in enhancing decision-making processes.

You're leveraging predictive modeling to forecast potential threats and resource needs, enabling proactive strategy adjustments. Data visualization techniques transform complex datasets into clear, actionable insights, greatly enhancing your operational awareness and response capabilities.

These tools integrate machine learning algorithms to sift through and analyze vast amounts of data from C5ISR systems, drones, and IoT devices. This not only speeds up your decision-making but also increases accuracy, reducing reliance on assumptions.

Data-Driven Strategy Enhancement

Leveraging real-time data analytics greatly enhances your decision-making capabilities by integrating various streams of information from drones, satellites, and ground sensors.

By employing IoT devices, you're not just collecting data; you're enabling a seamless flow into secure networks. This integration supports the use of predictive modeling and data visualization tools that transform raw data into actionable intelligence promptly.

Predictive analytics allow you to forecast potential threats and resource shortages, giving you a proactive stance in operational strategy.

This capability guarantees that you're not merely reacting to challenges but are prepared ahead of time, markedly reducing operational risks and optimizing resource allocation.

Embrace these innovations to maintain a competitive edge and adapt swiftly to ever-evolving operational environments.

Performance Monitoring Techniques

Real-time data collection and integration are essential for monitoring tunnel boring machine (TBM) performance effectively. By employing IoT technologies and data acquisition tools capable of handling Big Data, you're equipped to gather and analyze vast amounts of information from machine sensors, environmental conditions, and geological surveys.

This integrated approach guarantees that performance metrics aren't only precise but also actionable.

Through sensor integration, your system continuously feeds data into predictive analytics models that anticipate maintenance needs and potential operational risks. This capability allows for the optimization of maintenance schedules and minimizes downtime, enhancing operational efficiency.

Real-time analytics empower you to make swift, informed decisions, drastically improving response strategies and overall mission effectiveness in tunnel construction scenarios.

The Impact of Virtual Reality on Training and Simulation

As virtual reality technologies evolve, they greatly enhance the training and simulation processes for missile operations.

You'll find that the integration of VR with 6DOF dynamics allows for highly immersive experiences, closely simulating complex missile maneuvers and targeting strategies. This immersion is deepened by hyperrealistic environments where you can interact with dynamic scenarios in real-time, such as adjusting for sunlight in combat simulations.

The roar of rocket engines and the pursuit of targets augment these training simulations, providing an enveloping sense of presence and urgency.

Moreover, the advanced VR tools employ AI to render realistic behaviors of both allies and adversaries, enhancing strategic training efficacy.

With real-time feedback, your proficiency in missile operations will improve, leveraging personalized training that adapts to your performance metrics.

Environmental Considerations in Modern Missile Boring Practices

You must prioritize reducing soil contamination in missile boring by selecting advanced, steerable bore heads that guarantee precision and limit off-path drilling.

Minimizing habitat disruption is vital, employing techniques that avoid extensive surface excavation to preserve local ecosystems effectively.

Additionally, enhancing waste management involves meticulous on-site handling of drilling mud and other byproducts to prevent environmental spillage and pollution.

Reducing Soil Contamination

To effectively reduce soil contamination, modern missile boring practices now incorporate advanced technologies that both minimize environmental impact and enhance remediation efforts.

One innovative method involves the use of steam injection combined with auger mixing. This approach advances an 8-foot diameter auger to depths up to 60 feet, where steam heats the soil, effectively desorbing volatile organic compounds (VOCs). These VOCs are then volatilized and captured at the surface for treatment.

Concurrently, slurried micro-scale zero-valent iron (ZVI) is injected to facilitate the dechlorination of chlorinated solvents, achieving over a 99% reduction in contaminants like trichloroethylene (TCE) in both soil and groundwater.

This dual-action soil treatment underscores a robust strategy for contamination prevention in sensitive environments.

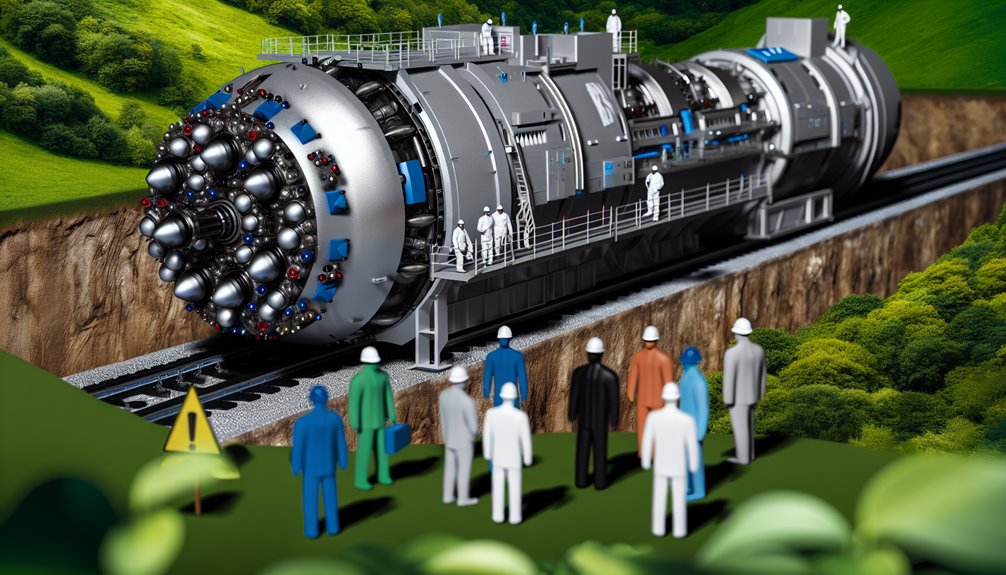

Minimizing Habitat Disruption

Building on the foundation of reduced soil contamination, modern missile boring techniques also focus greatly on minimizing habitat disruption.

Horizontal directional drilling (HDD) not only shortens setup times but guarantees precision in avoiding ecologically sensitive areas. This method considerably limits earth removal and surface damage, safeguarding natural habitats and preserving biodiversity.

By using HDD, you're committing to protecting wildlife habitats from excessive noise and physical disturbances, aligning with stringent environmental regulations. Additionally, the minimal impact on vegetation and avoidance of large-scale excavation are vital for habitat preservation.

This approach not only enhances wildlife protection but also maintains the integrity of ecosystems, making it a preferred choice in environmentally sensitive projects.

Enhancing Waste Management

As modern missile boring practices evolve, a primary focus is the enhancement of waste management to mitigate environmental impacts.

Here's how you can implement innovative waste management strategies in your operations:

- Utilize Natural Bentonite: Choose bentonite, a volcanic ash-derived substance for drilling mud, which offers natural properties that minimize environmental harm.

- On-site Disposal Solutions: For large-scale projects, develop on-site disposal methods that prevent contamination of local soil and water resources.

- Comprehensive Spoil Management: Properly handle and dispose of spoils and drilling mud to avoid environmental degradation.

- Continuous Compliance Monitoring: Verify all waste management practices comply with current environmental regulations, adapting strategies as necessary to meet safety standards.

Future Trends: Where Missile Boring Technology Is Headed Next

What does the future hold for missile boring technology?

You're looking at a landscape where future innovations aren't just possibilities, but imminent realities. Industry predictions focus on several advancements poised to redefine efficiency and precision. Enhanced accuracy will soon be achieved through sophisticated surveying technologies, minimizing deviations and maximizing operational throughput.

Integrated automated systems promise to revolutionize the boring process, enabling real-time adjustments and reducing human error.

Materials science is also advancing rapidly, with novel composites designed for extreme soil conditions, ensuring durability and cost-effectiveness.

Additionally, expect significant strides in environmental sustainability, including minimized ecological disruptions and increased energy efficiency.

These trends aren't just reshaping missile boring; they're setting new standards for the entire construction sector.

Conclusion

As you've seen, the advancements in missile boring contractor services are revolutionary. AI's precision, combined with robotic automation, not only boosts safety but also efficiency. The adoption of advanced materials and 3D printing allows for durable, custom equipment tailored to specific needs. In addition, integrating real-time analytics and virtual reality into operations enhances decision-making and training. With these technologies prioritizing environmental health, the future of missile boring looks both innovative and sustainable. Keep an eye on these evolving trends.

If you're curious to learn more about these exciting developments, I invite you to visit Boring Bros at boringbro.com or give us a call at (954) 639-6167. We'd love to chat with you and share how we can help with your missile boring needs!