If you’re upgrading utilities under a driveway, trenchless boring lets you avoid long sawcuts, slab removal, and irrigation repairs. You’ll use guided pilot drilling and staged reaming to hold line/grade, then pull new conduit with minimal surface disturbance. Closed-loop drilling fluid and on-site recycling limit frac-out risk, and vacuum potholing at tie-ins targets only what’s needed. Expect faster restoration and lower repair costs—but pricing, soil conditions, and clearances can change the plan.

What Trenchless Boring Is and When to Use It

Although it avoids open-cut excavation, trenchless boring (horizontal directional drilling, guided auger boring, or pipe ramming) still installs new or replacement utilities along a controlled subsurface alignment.

You select the method based on drive length, diameter, depth, and tolerance for line/grade. Define objectives, then verify feasibility with utility mapping, soil testing, and geotechnical baselines. Use ASTM F1962 for pullback force estimates, ASTM D2487 for soil classification, and ASCE 38/CI/ASCE 75 for subsurface utility data fidelity.

Choose HDD for curved alignments and continuous pipe; use guided auger boring for precise grade-sensitive gravity mains; apply pipe ramming for short, robust steel casings through cobbles.

Deploy when traffic disruption must be limited, crossings are congested, or environmental constraints restrict trenching. Document risks, contingency steering zones, and allowable tolerances.

How Horizontal Directional Drilling Minimizes Surface Damage

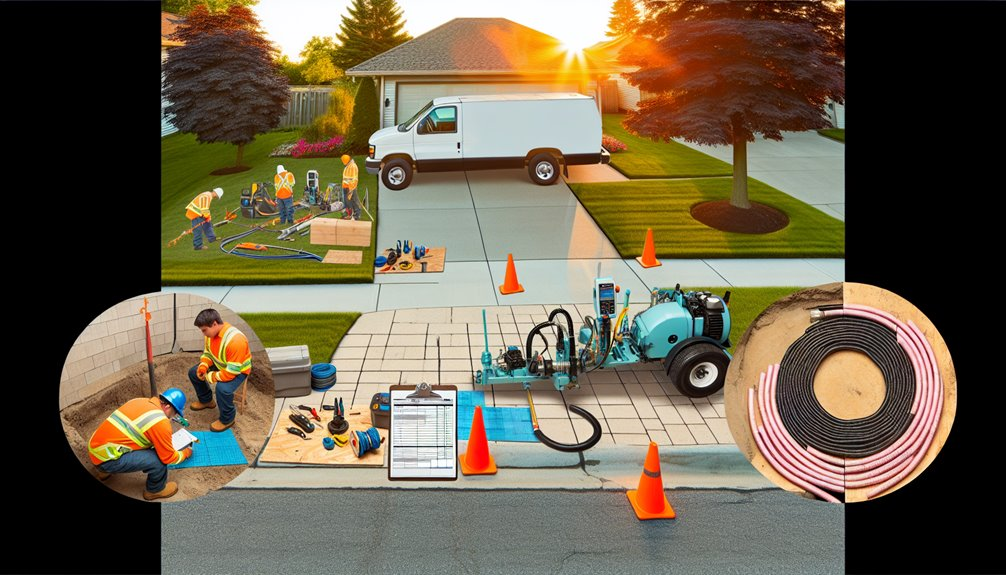

Building on method selection and feasibility checks, horizontal directional drilling (HDD) limits surface disturbance by confining activity to compact entry/exit pits and a controlled subsurface bore path, keeping pavement, landscaping, and habitats intact.

You steer the drill head with real‑time telemetry and gyroscopic guidance, maintaining line and grade per ASCE and ASTM standards.

HDD delivers Minimal disruption by avoiding open trenches, reducing haul‑off and compaction risk.

With Reduced landscaping impacts, you preserve root zones and irrigation lines while protecting driveways and sidewalks from sawcuts.

- Freshly bored arc beneath a driveway, surface untouched

- Two small pits, cones, and a clean rig footprint

- A restored lawn with no settlement seams

You verify tolerances via bore logs and as-builts, pressure-manage drilling fluids, and backream to right-size the annulus, preventing frac-out and safeguarding community assets.

Cost Breakdown and Factors That Affect Pricing

While trenchless boring reduces restoration costs compared to open-cut, your budget still hinges on a few quantifiable drivers: mobilization and setup (rig class, support trucks, fluid systems), geotechnical conditions (soil class per USCS, rock strength via UCS/RQD, groundwater), alignment geometry (length, depth, radius of curvature), pipe material and diameter (HDPE/PVC/steel per ASTM/CSA with wall thickness and pulling heads), utility congestion and SUE level (ASCE 38/75), traffic control requirements (MUTCD-compliant), drilling fluid volumes and additives (rheology, containment per EPA/SPCC), and QA/QC tasks (pilot logs, as-builts, pressure monitoring).

You’ll translate these into line items: mobilization hours and fuel, locator and recycler rates, Material costs for pipe, fittings, and tracking consumables, and Permit fees set by jurisdiction.

Add crew wages by certification, utility locates, vacuum excavation potholes, and fluid processing/disposal.

Include contingency for rock tooling and inadvertent return mitigation.

Bundle costs per LF with alternates for diameter changes.

Timeline: From Site Prep to Final Hookups

With costs scoped to line items and contingencies, you can map a schedule that aligns resources with constructible sequence.

Begin with site assessment: utility locates, geotechnical checks, and as-built verification (1–3 days).

Parallel permit coordination compresses lead time; submit traffic control and environmental documents early.

Mobilize for pilot bore after mark-outs cure.

Execute bore, ream, and pullback per ASTM F1962 and manufacturer tolerances.

Pressure test, mandrel, and disinfect as applicable.

Lock in inspection scheduling with the AHJ to avoid idle windows.

Final hookups proceed after pass/fail documentation, then restoration planning closes the loop—compaction tests, sawcut limits, and finish specs to protect your driveway.

- Painted utility marks drying on clean pavement

- Compact drill rig aligned with a laser target

- Freshly sealed driveway joints curing uniformly

Homeowner Prep Checklist and What to Expect During the Work

Start by locking down access, clearances, and documentation so field crews can stage and bore without delays. Confirm permit coordination with your municipality and utility; verify locate tickets are active (811) and markouts match plans. Provide neighbor notifications 48–72 hours ahead with dates, work hours, and parking impacts. Clear a 10–12 ft path for the drill rig and vacuum unit; protect landscaping with plywood or mats.

Expect pre-bore QA/QC: utility depth checks, entry/exit pit layout, fluid containment setup, and traffic control per MUTCD. During boring, you’ll see continuous tracking, mud recycling, and vac excavation at tie-in points. Noise stays within local thresholds. Crews maintain daily housekeeping and access to your driveway.

After pullback, verify as-built data, surface restoration, and punchlist closeout.

Conclusion

As the owner of Boring Bros., I can tell you trenchless boring really does protect driveways and landscapes — replacing long trenches with small pits, guided HDD, and closed-loop fluids means fewer sawcuts, faster restoration, and lower patch costs when line and grade matter or utilities cross pavements, landscaping, or irrigation. Before we start, we always confirm utility locates, soil data, setback clearances, and HDD rig access, and we verify contractors follow ASTM F1962, ASCE MOP 108, and manufacturer pullback limits so your upgrade is precise with minimal surface disruption. If you want to learn more or talk through a specific project, please visit boringbro.com or give us a call at (954) 639-6167 — we’d love to help.