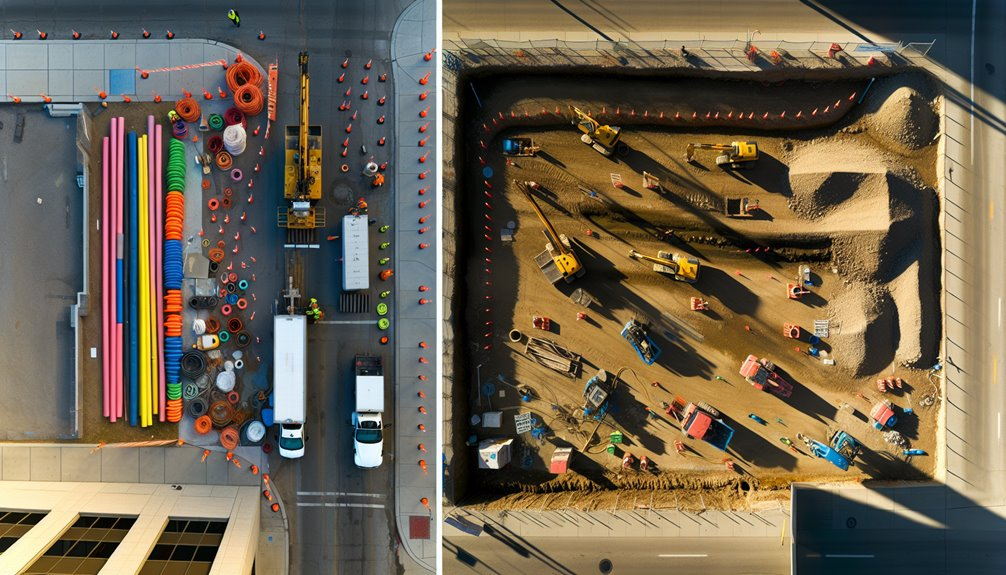

You’re weighing trenchless against open-cut for utility installation, and ROI hinges on hard numbers: capex vs. opex, schedule certainty, and risk of subsurface surprises. Trenchless often cuts traffic control, restoration, and business interruption costs while accelerating delivery. When you monetize detours, emissions, and claims, NPV and payback typically favor trenchless despite higher mobilization. Add reduced settlement risk and fewer maintenance interventions, and the total cost of ownership shifts—yet that’s only part of the equation.

Lifecycle Cost Breakdown: Capex, Opex, and Total Cost of Ownership

Before you choose trenchless or open-cut, map the lifecycle costs: capex, opex, and total cost of ownership (TCO).

Start with CapEx allocation: equipment mobilization, entry/exit pits, bypass systems, traffic control, surface restoration, and contingencies.

Normalize unit costs per linear foot and per depth class to compare apples to apples.

Then build Opex forecasting: inspection cycles, cleaning frequency, energy for dewatering or pump-arounds, corrosion protection, leak response, and pavement maintenance from settlement risk.

Quantify failure probabilities and embed them in expected-value TCO, discounted over asset life.

Include user-cost externalities (detours, business access) if they’re borne by your program.

Use sensitivity analysis on soil variability, diameter, and utility conflicts.

This lets you select the method with the highest risk-adjusted ROI your team can align behind.

Schedule Certainty and Delivery Speed Across Typical Project Scenarios

Although cost drives selection, schedule certainty often decides delivery, claims exposure, and ROI. You win time by aligning methods with context. In dense corridors, trenchless delivers accelerated mobilization, predictable sequencing, and 30–50% shorter critical paths by bypassing traffic control, utility relocation, and paving cycles.

For river, rail, and highway crossings, trenchless compresses permitting windows and eliminates multi-week closures, cutting outage durations by 40–70%.

On greenfield runs with wide easements, open-cut can match or beat trenchless in linear footage per day, but weather and haul logistics widen variance. Nightwork constraints favor trenchless: fewer crews, fewer shifts, less setup/tear-down.

Your schedule risk register shrinks when you minimize surface interfaces, simplify inspections, and parallelize pre-reaming, pipe stringing, and tie-ins. Faster, more reliable completion protects revenues and community goodwill.

Risk Profiles: Subsurface Unknowns, Change Orders, and Claims

Even with tight estimates, your ROI swings on how each method handles subsurface uncertainty and commercial fallout. Trenchless reduces exposure by limiting excavation volume and interfaces; fewer utility crossings translate into lower Subsurface liabilities per linear foot. With proper geotech (CPT, GPR, HDD pilot logs), you’ll quantify variance bands and price risk explicitly. Open-cut often triggers scope growth when utilities deviate from as-builts, amplifying change orders and delay costs.

Model the delta: expected value of unknown conflicts × probability × cost to resolve. Trenchless typically posts fewer field directives and narrower claim windows, shrinking contingency from, say, 20–30% to 10–15%. Clear differing-site-conditions clauses, risk registers, and unit-rate menus curb Contract disputes. Align incentives: share savings on obstruction avoidance, cap relocation exposure, and set decision SLAs to contain claim tails.

Community and Traffic Disruption: Monetizing Social and Business Impacts

Because lane closures, detours, and noise convert directly into economic drag, you should quantify them as cash flows in your ROI. Translate disruptions into unit costs: dollars per hour of transit delays, per day of parking loss, per block of impaired pedestrian flow. Assign penalties for noise complaints, event cancellations, and school schedules deviations. Model public safety exposure using response-time deltas tied to emergency access restrictions. Capture local business revenue impacts via footfall elasticity during construction windows.

For open-cut, apply longer disruption durations and wider impact radii; for trenchless, reduce time-in-street and surface restoration multipliers. Discount by community trust effects: faster, quieter methods lower reputational risk and future approval friction. Sum these externalities alongside direct costs to reveal trenchless’s superior net-present value under urban demand conditions.

Environmental and Permitting Considerations That Shift the Balance

While capital budgets focus on crews and pipe, permits and environmental constraints often swing ROI more than mobilization costs. You’ll see it in timelines: environmental permitting can add 60–180 days to open-cut when dewatering, tree removal, or stream crossings trigger agency review.

Trenchless methods frequently compress that window by avoiding surface disturbance, reducing impact footprints by 70–90%. That lowers surveys, public notice cycles, and habitat mitigation obligations.

You also cut spoil disposal, truck trips, and emissions, which many jurisdictions now price via carbon or haul fees. Fewer water-quality exceedance risks mean fewer stoppages and penalties.

Model it: assign dollars to permitting hours, studies, mitigation acreage, and monitoring. When you quantify avoided impacts, trenchless often returns 10–25% NPV gains through faster approvals and reduced compliance scope.

Long-Term Asset Performance, Reliability, and Maintenance Strategies

Once construction ends, lifecycle performance dictates ROI more than the bid price.

With trenchless, you typically gain tighter grade control, fewer joints, and reduced surface load impacts, which lowers infiltration, exfiltration, and settlement risk. You also preserve pavement integrity, cutting future restoration CAPEX.

Open-cut can deliver comparable reliability if you specify bedding, compaction, and corrosion control rigorously, but it’s more exposed to traffic-induced fatigue and reinstatement defects.

Design for uptime: choose materials with verified fatigue curves, abrasion indices, and lining compatibility. Embed serviceability design provisions—access points, standardized fittings, and sensor ports—to shorten mean time to repair.

Instrument assets for predictive maintenance, linking pressure transients, vibration, and cathodic data to failure models. Track mean time between failures and lifecycle cost/KPI dashboards to sustain budget certainty and community trust.

Conclusion

As the owner of Boring Bros., I’ve seen firsthand how trenchless installation delivers better ROI in urban and constrained corridors — cutting traffic control and surface restoration costs, reducing contingencies for unknowns, and driving lower total cost of ownership. Faster, more predictable schedules also lessen financing pressure and change-order risk, and once you monetize externalities like detours, lost business and emissions, the NPV and payback look even stronger. Environmental permitting is often simpler, and long-term settlement and maintenance risks go down. I encourage you to run lifecycle and scenario models to quantify capex, opex, and risk-adjusted cash flows for your project — in most cases trenchless comes out ahead. If you want to chat about a specific job or see case studies, visit boringbro.com or give us a call at (954) 639-6167 — we’d love to help.