As you explore the domain of missile boring contractors, you'll find that the core of their efficiency lies in the sophisticated machinery they wield. These technologies, from advanced cutting heads to modular construction components, are pivotal for precise subterranean installations. Techniques like Horizontal Directional Drilling (HDD) and microtunneling minimize ecological disruptions, proving indispensable in urban infrastructure projects. Understanding how these components interact and the challenges they address will reveal the nuances of this intricate field, inviting further exploration into its strategic applications.

The Evolution of Missile Boring Technology

As the demand for non-invasive underground installations grew, missile boring emerged as a pivotal technology in the field of construction and utility installation. Originating as a lower-cost solution, missile boring was initially used for precise installations in congested urban areas where traditional excavation was either impractical or too disruptive. This method, evolving from older boring techniques, leveraged advancements in pneumatic tools and air systems, greatly enhancing its feasibility and range. You'll appreciate the historical significance of missile boring, which revolutionized how utilities were installed beneath cities, reducing both financial strain and environmental impact. However, its early limitations, like the length of the air supply hose and difficulties with certain soil types, gradually shaped the innovations that followed in equipment and methods. Recent developments in rapid tunneling technologies have further influenced the efficiency and capabilities of missile boring, integrating more sophisticated navigation systems and real-time data analysis for precision drilling.

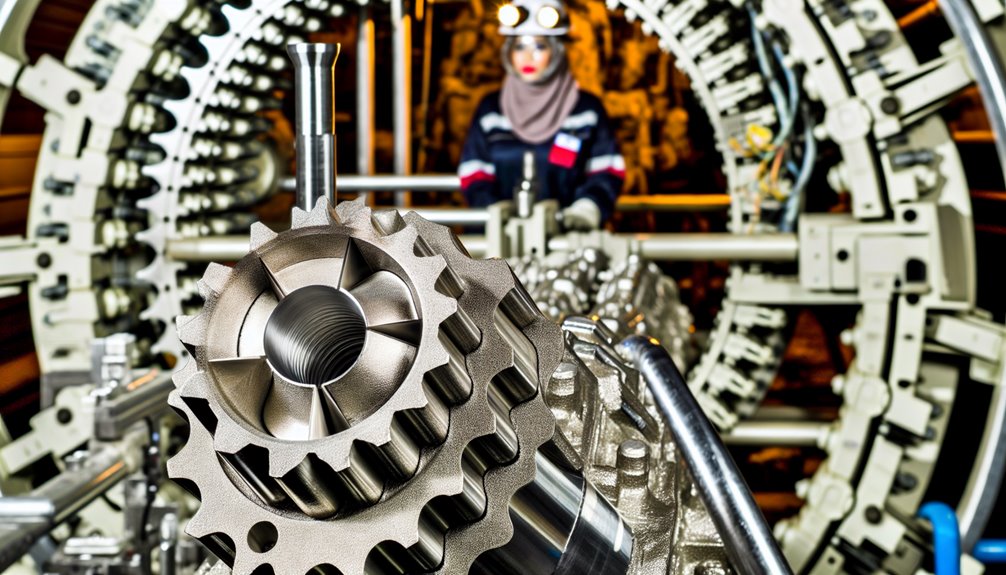

Key Components of Modern Missile Boring Machines

Understanding the evolution of missile boring technology sets the stage to explore the key components that define modern missile boring machines.

Here's what you need to know about the vital elements:

- Cutter Head Technology: Advanced cutter heads are engineered for efficient rock interaction, minimizing wear and adapting to different rock types, essential for maintaining high performance in diverse geologic conditions.

- Modular Components: Flexibility is key; components, especially the cutter heads, can be swapped to optimize the machine for specific tasks and environments, enhancing adaptability and efficiency.

- Muck Handling: Efficient systems are integral for removing excavated material, ensuring seamless operation with minimal downtime, and maintaining the pace of progress.

- Control and Guidance Systems: Precision in excavation is enhanced by sophisticated GPS and automation technologies, providing high accuracy and safety during operations. Additionally, the use of adaptive drilling technology improves the machine's performance by adjusting to varying geological conditions in real-time.

The Role of Advanced Algorithms in Subterranean Drilling

As you explore the role of advanced algorithms in subterranean drilling, consider how optimization techniques enhance the precision of drilling parameters.

Real-time data analysis, powered by AI, enables you to monitor operations continuously, adjusting strategies promptly to optimize performance and safety.

These tools not only streamline processes but also mitigate risks, transforming how underground drilling projects are executed.

Algorithm Optimization Techniques

While exploring the depths of subterranean environments, advanced algorithms play a pivotal role in enhancing drilling efficiency and precision.

You'll find that reinforcement learning, particularly in automated history matching, is critical:

- Iterative Learning: This technique refines predictions about subsurface characteristics, such as porosity and permeability, through continuous feedback and adjustments.

- Bias Reduction: Unlike traditional methods, reinforcement learning doesn't assume pre-existing data patterns, reducing bias and enhancing model accuracy.

- Sequential Decision-Making: Automated history matching views the process as a series of decisions, improving efficacy and reducing human intervention.

- Efficiency Gains: Over time, these algorithms learn to simulate even complex reservoirs more accurately, markedly boosting computational efficiency.

Real-Time Data Analysis

Real-time data analysis transforms how you monitor and optimize drilling activities by employing advanced algorithms capable of processing information as it emerges from the depths.

This approach integrates real-time monitoring with data visualization tools, enabling you to see the drill bit's progress and make decisions based on current conditions.

By visualizing real-time data such as azimuth, inclination, and gamma ray, you can adjust drilling parameters like weight on bit (WOB) and torque instantly.

Advanced algorithms also analyze data from downhole sensors, detecting anomalies like stick-slip or whirl before they escalate.

Consequently, you're not just collecting data; you're actively using it to enhance operational efficiency, reduce risks, and predict drilling outcomes more accurately.

Challenges and Solutions in Horizontal Directional Drilling

Maneuvering through the complexities of horizontal directional drilling (HDD), you must confront several challenges that stem from varying soil and rock conditions, existing utilities and obstacles, restricted workspaces, and significant weather fluctuations.

To address these, consider the following strategies:

- Utility Mapping and Safety: Employ ground-penetrating radar and electromagnetic tools for accurate utility mapping, enhancing drilling safety and preventing service disruptions.

- Equipment Selection: Choose drilling tools and mud systems that are specifically tailored to the soil and rock conditions you're dealing with.

- Weather Adaptation: Utilize arctic grade equipment and modify drilling fluid properties to cope with extreme temperature variations.

- Space Management: Opt for compact drilling rigs and collaborate closely with local stakeholders to navigate restricted workspaces effectively.

These approaches guarantee you're prepared to tackle HDD projects with precision and innovation.

Environmental Considerations in Missile Boring Operations

As we explore the environmental considerations in missile boring operations, it's important to recognize the method's inherent advantages in preserving the natural landscape and minimizing ecological disruption.

You'll find that missile boring considerably reduces soil disruption, thereby mitigating soil erosion and preserving soil health. This technique maintains microbial communities and nutrient cycles, essential for robust soil ecosystems.

Moreover, the localized nature of its impact helps in safeguarding groundwater from contamination—a crucial aspect of environmental protection.

Importantly, habitat conservation is prioritized; missile boring minimizes the physical disturbance to habitats and noise pollution, which could otherwise disrupt wildlife.

This method proves instrumental in maintaining ecological balance by keeping the natural state of environments largely intact.

Case Studies: Successful Missile Boring Projects

You've seen how missile boring technology transforms landscapes with minimal disturbance; now, let's explore specific case studies that highlight urban infrastructure enhancements, cross-country pipeline installation, and coastal defense system upgrades.

Each project showcases the precision and adaptability of modern boring techniques in complex environments.

Analyzing these examples, you'll observe the strategic integration of advanced technology and meticulous planning in overcoming geographical and logistical challenges.

Urban Infrastructure Enhancements

While exploring the domain of urban infrastructure enhancements, it's clear that missile boring technology has greatly advanced the efficiency and reduced the invasiveness of urban utility installations.

Here are some key points you should consider:

- Minimizes Surface Disruption: By tunneling beneath obstacles, missile boring avoids the extensive surface damage typical of traditional excavation, preserving the aesthetics and functionality of urban areas.

- Environmental Friendliness: This method notably lessens ecological impact, supporting infrastructure sustainability in sensitive urban environments.

- Cost-Effectiveness: Lower restoration needs coupled with faster completion times translate into reduced costs, facilitating broader urban development projects.

- Precision and Versatility: High accuracy in utility placement minimizes disruptions to urban life, showcasing the adaptability of missile boring across various infrastructure scenarios.

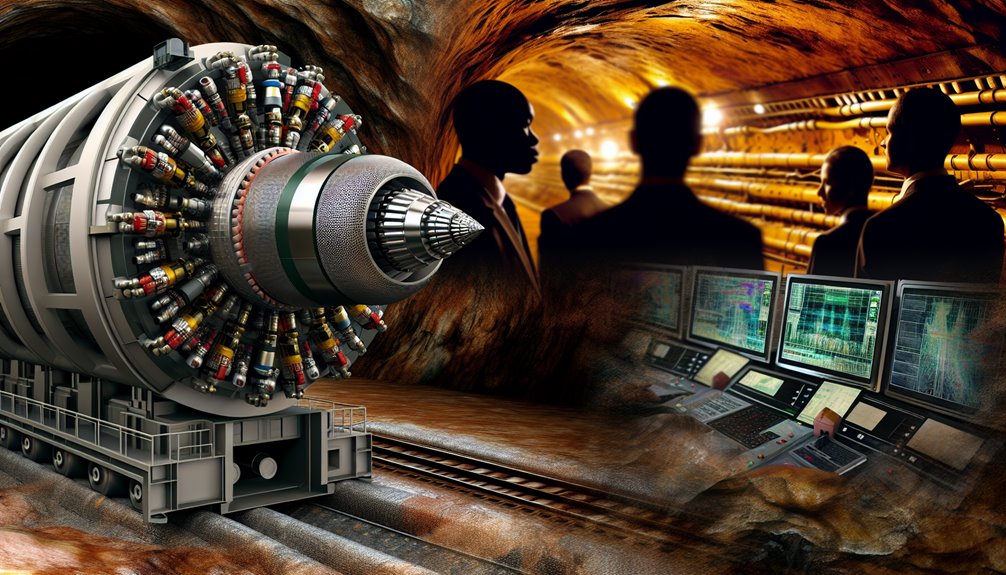

Cross-Country Pipeline Installation

Although urban infrastructure projects often gain the limelight for their complexity and impact, cross-country pipeline installations represent an equally challenging endeavor where missile boring technology has proven transformative.

You'll find that techniques like Horizontal Directional Drilling (HDD) revolutionize pipeline routing, allowing installations under rivers and roads with minimal ecological disturbance.

Microtunneling, another advanced method, offers precision in complex terrains, ensuring pipelines are installed without surface disruption.

Both techniques emphasize strategic planning in site preparation, particularly in pinpointing existing utilities and evaluating geotechnical conditions.

Additionally, with the sophisticated management of resources such as selecting appropriate HDD machinery and utilizing bentonite drilling fluids, these installations not only meet stringent regulatory standards but also set benchmarks in environmental conservation and technical innovation.

Coastal Defense System Upgrades

As coastal threats escalate, upgrading defense systems has become essential. Here's how missile technology advancements are shaping coastal defense strategies:

- Speed and Range Enhancements: Recent improvements in Standard Missiles leverage advanced materials, boosting their operational range and speed, vital for intercepting long-range threats.

- Efficient Propulsion Systems: The adoption of Dual Combustion Ramjets provides superior performance in hypersonic flight regimes, enhancing missile responsiveness against fast-moving targets.

- Vertical Launch Dynamics: The integration of Vertical Launching Systems in platforms like Aegis Guam guarantees rapid deployment capabilities, vital for sudden maritime threats.

- Thermal Resistance: Enhanced thermal protection systems maintain missile integrity during high-speed travel, guaranteeing effectiveness upon target impact.

These upgrades signify a robust evolution in defending coastlines through cutting-edge technology.

Future Trends and Innovations in Missile Boring Technology

Exploring future trends and innovations in missile boring technology reveals a focus on overcoming existing challenges and enhancing operational capabilities.

You'll witness emerging technologies that enhance precision and expand the scope of soil compatibility, critical for future applications. Incremental boring and advanced equipment integration will allow deeper, longer bores, even in challenging conditions like rocky or coral soils.

Furthermore, the integration of automated systems promises to streamline operations, boosting both speed and accuracy. As you investigate further, cost-efficiency will continue to improve, with ongoing research aimed at reducing expenses without compromising quality.

Embrace these advancements, as they guarantee compliance with evolving regulatory standards and foster a safer, more efficient boring environment.

Conclusion

As you investigate missile boring technology, it's clear the precision and minimal ecological impact are critical. The advanced algorithms and robust machinery you've explored not only enhance efficiency but also guarantee sustainability. Facing challenges like HDD complexities, the continuous innovations and solutions highlighted notably push the boundaries of subterranean engineering. Keep an eye on future trends, as ongoing advancements promise to further refine the capabilities and environmental friendliness of missile boring operations in urban and sensitive areas.

If you're curious to learn more about how missile boring can benefit your projects, I invite you to visit Boring Bros at boringbro.com. You can also give us a call at (954) 639-6167. We'd love to chat with you and share more about our innovative solutions!