You should choose HDD over open‑cut when surface disruption, access, and traffic continuity are non‑negotiable. In dense corridors with utility congestion, shallow groundwater, or mixed fills, HDD reduces strike risk, settlement, and long‑term pavement defects. It also limits outages near transit, hospitals, and businesses, and mitigates impacts across riparian buffers or contaminated soils. Pair it with solid geotech mapping, telemetry, and frac‑out controls. But there are cases where open‑cut still wins—here’s how to decide.

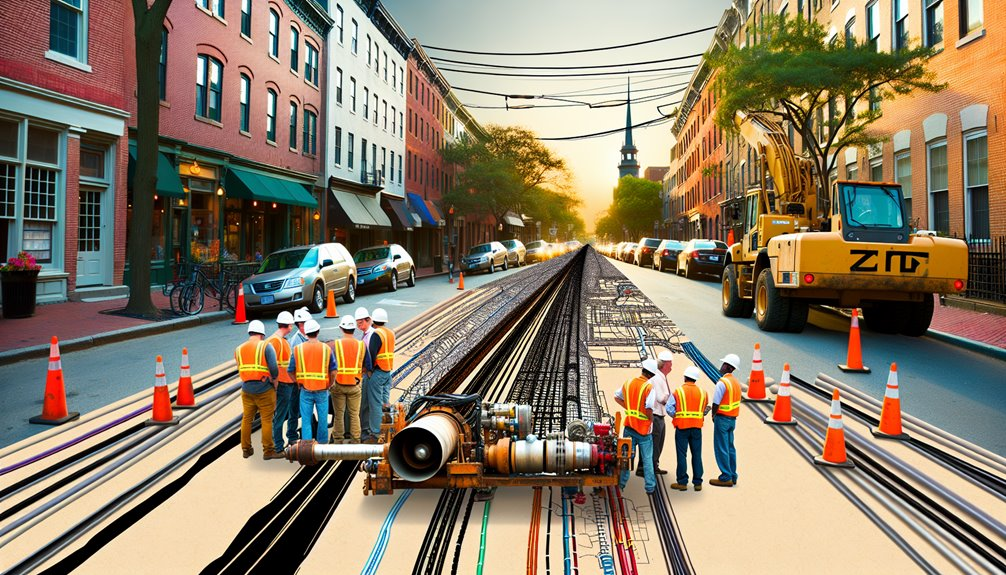

Assessing Urban Density and Surface Disruption

When you evaluate trenchless options in a city core, start by quantifying urban density and mapping where surface disruption carries the highest penalty. You’ll build your case for HDD by scoring block-by-block conditions: land use intensity, frontage types, pedestrian flow peaks, transit adjacency, and emergency access. Combine parcel data, footfall sensors, and curb inventory to weight sensitivity along the alignment.

Model subsurface risk in parallel: utility congestion, abandoned assets, soil variability, groundwater, and settlement-prone zones. Calibrate strike probability and heave potential to your route classes. Where mixed-use clusters, tight sidewalks, and high pedestrian flow coincide, elevate HDD preference to protect continuity of street life and business operations. Document assumptions, uncertainty bands, and mitigation triggers so your team aligns on thresholds before design commitments.

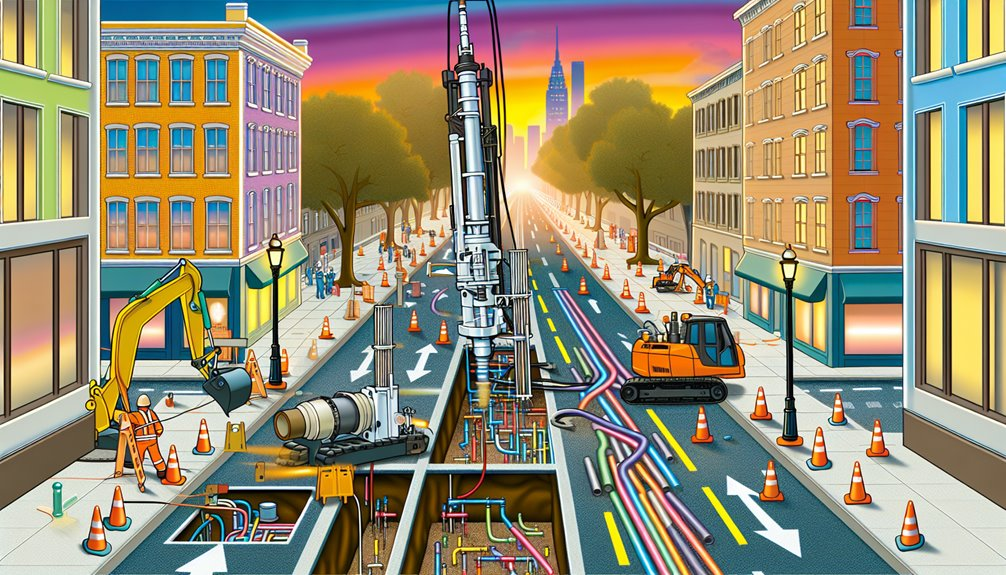

Traffic Management and Lane Closure Minimization

Start by locking down a traffic management plan that treats lane capacity as a scarce asset and prices every closure against network performance and safety risk.

You’ll translate demand into measurable throughput targets, then choose HDD when it maintains flow with minimal footprint.

Define detour hierarchy, peak-period restrictions, and a trigger matrix that shifts you from open-cut to trenchless when queue length, delay, or crash risk exceed thresholds.

Use staggered closures to avoid concurrent bottlenecks across adjacent corridors.

Where you must occupy space, deploy a temporary lane using narrow shoulders, dynamic cones, and smart signal timing to preserve progression.

Model work-zone capacity with V/C, HCM control delay, and shockwave analysis.

Schedule micro-windows at off-peak periods.

Monitor with probe data, and adapt in near-real time to keep everyone moving.

Protecting Existing Utilities and Avoiding Strikes

Although HDD reduces surface disruption, you still treat subsurface utilities as critical constraints that drive method, alignment, and risk controls.

You begin with high-resolution utility mapping: consolidated records, electromagnetic and GPR sweeps, and potholing to verify depth, material, and tolerance. You then set minimum clearances per asset class and codify them in the bore plan, entry/exit geometry, and steering envelopes.

For strike prevention, you deploy calibrated walkover or wireline guidance, real-time depth/azimuth checks, and continuous as-built logging. You require daylighting at all conflict points, lockout/tagout near energized plant, and drill fluid programs that limit inadvertent returns around conduits. You brief crews on trigger thresholds, hold points, and stop-work authority.

Finally, you coordinate with owners for standby oversight and contingency response.

Noise, Vibration, and Community Disturbance Considerations

Frequently overlooked early, noise and vibration become primary constraints for HDD in dense corridors, shaping equipment selection, work windows, and mitigation budgets. You should quantify baseline ambient levels, then model drill rig, mud pump, and vac truck spectra to predict façade and interior exposures. Set criteria aligned to municipal limits and occupant sensitivity (residential nights, schools, hospitals), and make sound mitigation a line item, not an afterthought. Pair this with community outreach that frames you as a neighbor, not a disruptor.

- Engineer controls: select low-dBA rigs, variable-speed pumps, isolated vac units; design barriers, enclosures, and resilient mounts; optimize tool RPM and thrust to limit vibration.

- Schedule intelligently: quiet hours, staged deliveries, and idle-reduction policies.

- Monitor and adapt: real-time noise/vibration telemetry, complaint hotlines, corrective action playbooks.

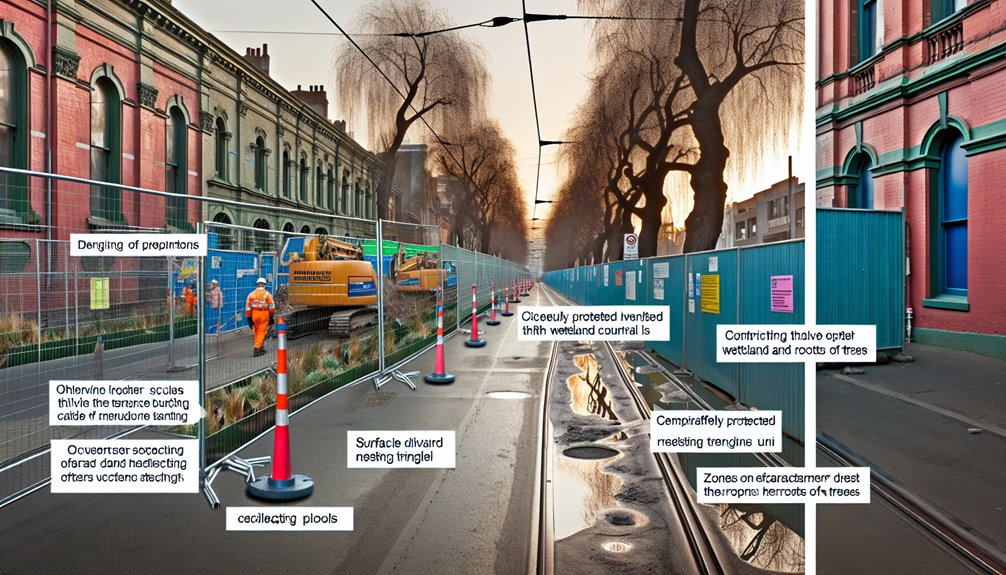

Environmental Constraints and Sensitive Corridor Crossings

Because urban corridors compress utilities and habitats into narrow rights-of-way, you must treat environmental constraints as primary design inputs, not permitting afterthoughts. HDD often outperforms open-cut when you face regulated riparian buffers, contaminated soils, or mapped wildlife corridors that can’t tolerate trench exposure. You reduce surface disturbance, maintain root zones, and protect streambanks.

Design with hydrogeology first. Specify drilling fluids, returns management, and annular pressure limits to achieve groundwater protection and prevent inadvertent returns. Use geophysics and utility locates to select profiles that avoid critical aquifers and buried debris fields. Where sensitive crossings are unavoidable, model frac-out risk, install containment, and stage vacuum recovery.

Coordinate with resource agencies early. Align bore depths beneath habitat, schedule around migration windows, and document monitoring triggers, thresholds, and stop-work protocols the field can execute.

Schedule Pressures and Night/Weekend Work Feasibility

Protecting habitats and groundwater doesn’t absolve you from aggressive urban schedules; it shapes how you meet them. HDD often outpaces open-cut when access windows are tight and permits steer you toward night shifts and weekend crews. You reduce surface disruption, compress critical path tasks, and keep stakeholders on your side by minimizing lane closures and noise footprints.

- Quantify constraints: map allowable work hours, vibration and noise limits, traffic control windows, and crew changeovers; align HDD rig capacity to trenchless drive lengths to eliminate idle time.

- Optimize sequencing: pre-stage pipe strings, fluids, and tooling; coordinate locates and inspections to run parallel with drilling to protect schedule float.

- Manage risk: prepare contingency bores, fluid loss control plans, and rapid-response utility strike protocols to keep after-hours work predictable and defensible.

Lifecycle Cost and Pavement Restoration Impacts

Even when capital budgets favor open-cut on bid day, you should model lifecycle cost with pavement restoration and long-tail risk in view. Initial trenching may look cheaper, but repeated patches degrade ride quality, reduce surface aesthetics, and trigger citizen complaints that turn into political cost. Quantify overlay cycles, joint failures, and utility-conflict repairs over 20–30 years.

HDD minimizes pavement disturbance, shrinking your restoration footprint and your liability tail. Include user-delay costs, lane-rental fees, and warranty exposure for reflective cracking. Compare net present value of long term maintenance: saw-cut joints, settlement monitoring, and thermoplastic re-striping versus HDD’s smaller reinstatement and fewer revisit events. Price inspection and after-action coring. Align with your city’s pavement management index targets and complete-streets commitments. Choose the method that protects the corridor’s lifecycle performance and community trust.

Geotechnical Conditions Favoring Trenchless Techniques

While soils vary block to block in cities, certain geotechnical conditions consistently tilt the balance toward HDD and other trenchless methods. You’re aiming for controlled steering, minimal disruption, and predictable productivity, so prioritize subsurface profiles that reward precision and reduce open-cut exposure.

- Cohesive, fine-grained strata: Silts and clays provide stable bore paths, maintain annular support, and limit void migration. They reduce inadvertent returns and let you set tighter curvature without compromising pullback.

- Heterogeneous corridors with soil anomalies: Mixed fills, buried debris, and utilities complicate trench walls. Trenchless routes can bypass obstructions, thread utility corridors, and localize risks through targeted pilot data.

- High water tables requiring Groundwater control: HDD confines fluid management to the bore, leverages drilling mud pressure to counter seepage, and avoids dewatering-induced settlement, protecting pavements and adjacent foundations.

Risk Management and Service Continuity Priorities

Although schedule and cost drive many decisions, you prioritize HDD in cities to harden risk posture and keep services online. You’re safeguarding service continuity by minimizing surface disruption, isolating crews from traffic conflicts, and reducing third‑party damage to buried assets. HDD’s smaller footprint limits outage exposure, shortens critical path interfaces, and preserves access for emergency response.

You quantify risk: map utility congestion, model strike likelihood, and price contingency against HDD’s controlled bore path. You also plan telemetry, frac‑out detection, and returns management to protect waterways and comply with permits. With preapproved detours, night shifts, and hot‑tap tie‑ins, you maintain customer uptime while sequencing work windows around hospitals, transit, and commerce.

Document triggers, thresholds, and comms protocols so your team acts fast when conditions drift.

When Open-Cut Remains the Practical Choice

Some corridors favor a trench. You choose open-cut when surface control, shallow depth, and predictable soils outweigh HDD’s precision. Trenching lets you verify clearances visually, sequence tie-ins cleanly, and compress testing and restoration within tight permit timing. It also mitigates steering risk near dense networks, provided utility coordination is disciplined and records are current.

- Cost and schedule integrity: Short runs with frequent service connections often deliver lower unit costs and faster closeout via trench, especially where night work or lane shifts are preapproved.

- Quality assurance: Direct bedding, compaction, and as-built verification reduce rework risk and simplify warranty obligations.

- Operational resilience: Emergency replacements, contaminated soils, or subsidence zones favor open-cut, where you can adapt methods in real time and maintain public safety with clear traffic control.

Conclusion

I’m the owner of Boring Bros., and my advice is simple: favor HDD when urban density, limited access, traffic continuity, and congested utilities make surface disruption costly and risky, but only after pairing it with rigorous subsurface mapping, fluid telemetry, and frac‑out controls to reduce strike probability, environmental harm, and outage exposure. Remember to account for lifecycle costs and pavement durability, not just the lowest bid. That said, I still recommend open‑cut where you’ve got shallow, conflict‑free corridors, benign soils, and short runs that allow rapid, low‑risk excavation — let geotechnical certainty and service continuity drive your method selection. If you want to learn more, visit boringbro.com or give us a call at (954) 639-6167 — we’d love to help.